High-Temperature Microstructural Stability of Modified Tungsten Materials

- Details

- Category: Tungsten's News

- Published on Monday, 29 May 2023 18:28

To assess the stability of the high-temperature microstructure of modified tungsten materials, including the recovery, recrystallization and grain growth stages, the Vickers hardness and grain size were measured after isothermal annealing at 1100-2300°C for 1 hour.

The general stages of the effect of annealing temperature on hardness are as follows: first, the microstructure recovery stage, where the hardness gradually decreases from the respective received value by about 10-20 HV with increasing annealing temperature; second, the primary recrystallization stage, where the value rapidly decreases from about 70-100 HV after the recovery stage; and third, a further gradual decrease of about 10 HV before 2300 °C.

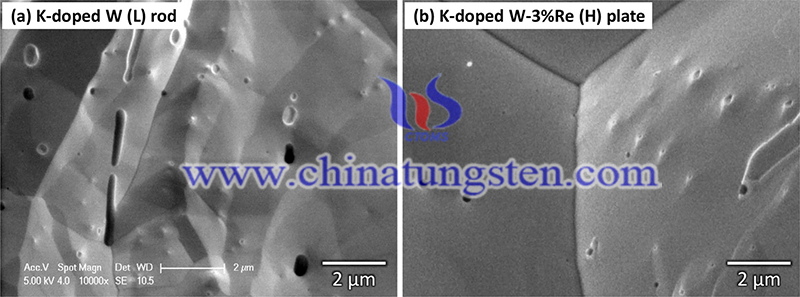

From these annealing temperature dependencies of Vickers hardness, the recrystallization temperature after 1 h of isothermal annealing for pure W(H) plate is 1250°C; 1350°C for K-doped W(H) plate; 1500°C for W-3% Re(H) plate; 1450°C for K-doped W-3% Re(H) plate; 1400°C for W-3% Re(L) plate; 1550°C for K-doped W-3% Re( L) plate at 1550°C; W-3% Re - 1% La2O3 (L) plate at 1550°C; pure W (H) rod at 1400°C; K-doped W (H) rod at 1600°C; pure W (L) rod at 1700°C; and K-doped W (L) rod at 1700°C.

The inner core average dislocation (KAM) can essentially indicate the average value of the difference in grain orientation. Therefore, processed materials with high density dislocations and recrystallized materials with very low-density dislocations can generally show high and low KAM values, respectively. According to the KAM images, the recrystallization temperatures of pure W(H) plates, K-doped W(H) plates and K-doped W-3% Re(H) plates are 1200-1300°C, 1300-1400°C and 1400-1500°C, respectively (blue color indicates low KAM), which are consistent with the recrystallization temperatures determined by hardness measurements above.

Reference: Nogami S, Hasegawa A, Fukuda M, et al. Mechanical properties of tungsten: recent research on modified tungsten materials in Japan[J]. Journal of Nuclear Materials, 2021, 543: 152506.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com