Latest Progress on Modified Tungsten Materials in Japan

- Details

- Category: Tungsten's News

- Published on Thursday, 25 May 2023 15:37

To develop modified tungsten materials, progress has been made in the development of irradiation-resistant W materials with improved thermomechanical properties over the past decade under collaborative university research and development in Japan. Researchers have developed grain refinement, work hardening, alloying, and dispersion strengthening aimed at improving the ductility and toughness of modified tungsten materials, even under neutron irradiation.

There are several special production methods to obtain materials with excellent properties, for example, ultra-fine grain (UFG) W-TiC compacts fabricated by powder metallurgy methods using mechanical alloying (MA), however, some methods have so far been limited to laboratory-scale material production. Therefore, the powder metallurgy method was chosen for this R&D project to obtain mass-produced W materials with microstructural uniformity.

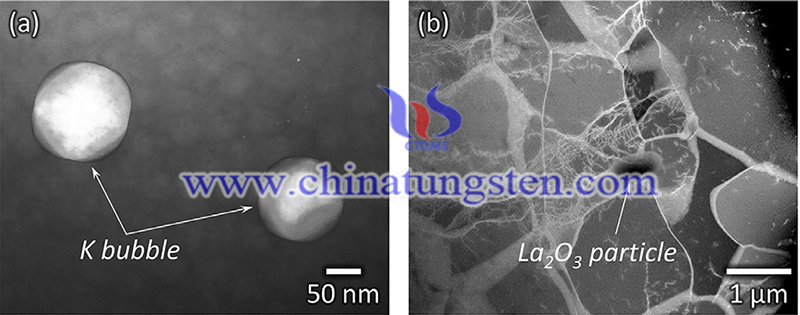

In a review article researchers discuss the effects of grain refinement, dispersion strengthening by potassium bubbles (K-doping), dispersion strengthening by lanthanum oxide (La2O3) particles and solid solution alloying by rhenium (Re) in terms of high temperature microstructural stability (recovery, recrystallization and grain growth), Charpy impact properties and tensile properties.

K-doping is a common method for dispersion strengthening of W materials and has historically been used for W filaments, among others. K-doped W contains nanobubbles (about ppm) including K atoms dispersed mainly at grain boundaries. k-bubbles are generated by volatilization of K during sintering, and K is added to the raw material powder. Since K-bubbles can impede the movement of grain boundaries and dislocations, they lead to strengthening and inhibit recrystallization at high temperatures. In addition, K-doping can produce finer grains compared to pure W because K-bubbles inhibit grain boundary migration. This grain refinement also leads to strengthening and toughening. A similar positive effect is expected by applying dispersion of La2O3 particles.

Alloying with Re is also a common method of solid solution alloying of W materials. It is well known that alternative solid solution elements in body-centered cubic (bcc) metals, such as Re in W, can cause solid solution strengthening at high temperatures and solid solution softening at low temperatures. solid solution Re in W materials can improve not only mechanical properties but also resistance to recrystallization and neutron irradiation. By adding Re, the changes in thermomechanical properties, recrystallization resistance and neutron irradiation resistance depend on the amount of Re added.

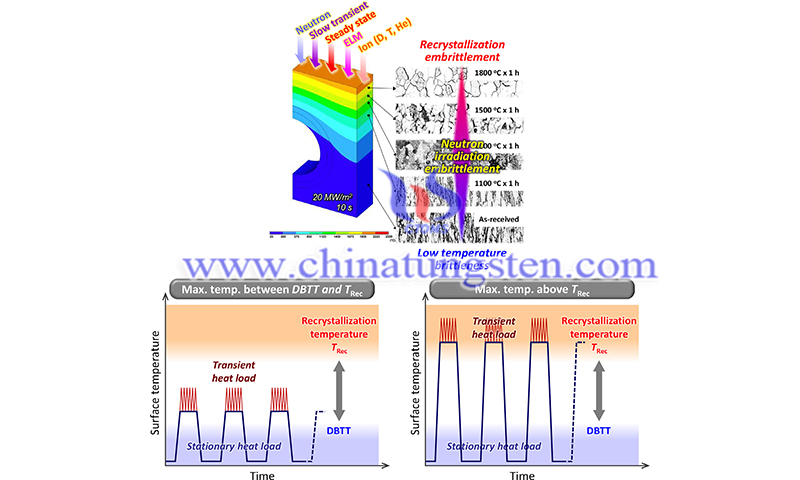

Future fusion reactors like DEMO are expected to operate for long periods of time. Therefore, the assessment of long-term structural reliability and lifetime is critical. For PFMs, time-dependent phenomena and properties such as cyclic fatigue, creep, creep-fatigue interactions, ratcheting, accumulation of plastic strain, long-term microstructural stability, and neutron irradiation effects should be evaluated. Therefore, the results of the evaluation of fatigue life, long-term microstructural stability and neutron irradiation effects of pure and modified W materials developed in this R&D project are also described in this paper.

In addition, the PFMs of the fusion reactor shunt will be subjected to complex thermal loads, including steady-state, transient, and ELM thermal loads. In these thermal load environments, integrated thermomechanical performance is important because various types of loads will be applied simultaneously. Material-related structural and lifetime limitations cannot be determined by considering material properties in isolation, but rather by evaluating synergistic loading effects.

Reference: Nogami S, Hasegawa A, Fukuda M, et al. Mechanical properties of tungsten: recent research on modified tungsten materials in Japan[J]. Journal of Nuclear Materials, 2021, 543: 152506.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com