Mechanical Properties of Tungsten: Recent Research on Modified Tungsten Materials

- Details

- Category: Tungsten's News

- Published on Thursday, 25 May 2023 15:15

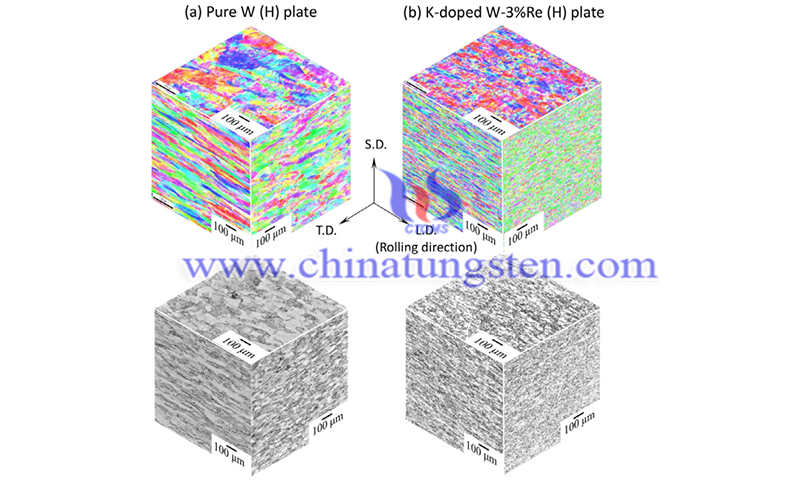

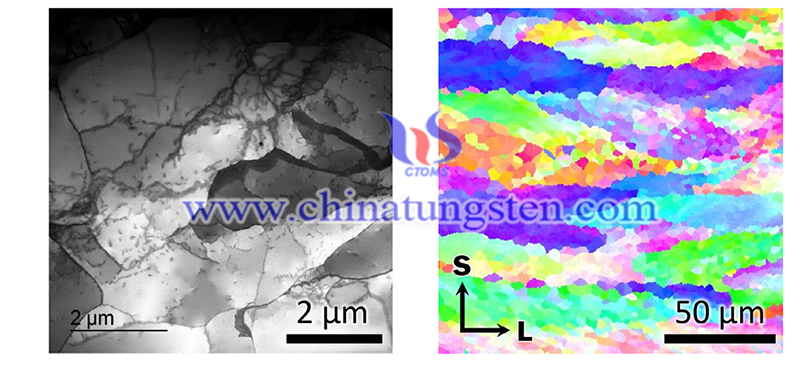

As a plasma-facing material (PFM) for fusion reactor steering, the mechanical properties of W materials still suffer from some defects, namely ductile-to-brittle transition temperature (DBTT) and brittleness due to recrystallization. To solve these problems, modified tungsten materials with improved thermomechanical properties, neutron irradiation tolerance, and microstructural homogeneity with mass production possibilities have been developed in the last decade with collaborative R&D at Japanese universities.

A research paper discusses the effects of grain refinement, K doping, dispersion strengthening of La2O3 particles, and Re alloying from the perspective of short- and long-term material properties and phenomena, including the effects of neutron irradiation and high thermal loads, that should be considered in a real fusion reactor environment. Through this development, K doping and Re addition show some positive effects.

A research paper discusses the effects of grain refinement, K doping, dispersion strengthening of La2O3 particles, and Re alloying from the perspective of short- and long-term material properties and phenomena, including the effects of neutron irradiation and high thermal loads, that should be considered in a real fusion reactor environment. Through this development, K doping and Re addition show some positive effects.

The estimated steady-state heat flux in the PFMs of future fusion reactor steering will be about 5-10 MW/m2. However, transient heat loads of up to about 20 MW/m2 or higher must be considered for safety reasons due to the possibility of abnormal events. In the case of edge-localized mode (ELMs) discharges, the steady-state heat load will be superimposed by short pulses in the GW/m2 range. Depending on the specific operating scenario, there are different possible degradation processes that will limit the lifetime of the plasma-oriented steering components. For example, the degradation of the physical and mechanical properties of the PFM may be due to surface modification, cracking, deformation, aging, recrystallization, and melting.

In addition to thermal loading, PFMs are subject to damage from neutron irradiation, which may include displacement damage (hardening, void expansion, radiation-induced deflection or dissolution, etc.) and transmutation damage (formation of phases due to transmutation products, etc.). Most of these irradiation effects lead to embrittlement and other degradation of PFM properties. Therefore, both thermal load conditions and neutron irradiation must be considered to assess the operational limits of the shunt components.

In addition to thermal loading, PFMs are subject to damage from neutron irradiation, which may include displacement damage (hardening, void expansion, radiation-induced deflection or dissolution, etc.) and transmutation damage (formation of phases due to transmutation products, etc.). Most of these irradiation effects lead to embrittlement and other degradation of PFM properties. Therefore, both thermal load conditions and neutron irradiation must be considered to assess the operational limits of the shunt components.

The upper and lower limits of the operating temperature of steering components using W materials will be determined by the recrystallization temperature and DBTT, respectively. However, neutron irradiation can increase the DBTT and potentially change the recrystallization temperature. Therefore, the operating temperature range determined by the recrystallization temperature and DBTT may be reduced by neutron irradiation.

Reference: Nogami S, Hasegawa A, Fukuda M, et al. Mechanical properties of tungsten: recent research on modified tungsten materials in Japan[J]. Journal of Nuclear Materials, 2021, 543: 152506.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com