Modified Tungsten Materials by K-Doping, La2O3 Particles Dispersion, and Re Alloying

- Details

- Category: Tungsten's News

- Published on Thursday, 25 May 2023 15:42

K-doping, dispersion of La2O3 particles, and Re alloying have been mainly used as modification methods for modified tungsten materials. To clarify the effect of these modifications, the main conditions of the basic production route were the same for all materials, including cold isostatic pressing, sintering, rolling or forging, and finally heat treatment for stress relief. In order to study the effect of the reduction rate (deformation rate) in rolling and forging, several levels of deformation rates were used.

The researchers fabricated plates made of pure W, K-doped W, W-3%Re, K-doped W-3%Re, and W-3%Re-1%La2O3 and tungsten rods made of pure W and K-doped W. The concentration of K in K-doped W and K-doped W-3%Re is about 30 ppm. The K-bubbles and La2O3 particles are mainly dispersed at grain boundaries, hindering the movement of grain boundaries and dislocations, thus making finer grains, higher strength, and inhibiting recrystallization. The amount of Re addition (3%) is determined based on the understanding of the changes in mechanical properties, thermal conductivity, resistance to recrystallization, and resistance to neutron irradiation by Re addition.

The plates are manufactured by powder metallurgy and hot rolling, followed by a final heat treatment at 900°C for 20 minutes to relieve stress. The deformation rates for hot rolling are divided into two grades; the higher grade (denoted by "H" below) and the lower grade (denoted by "L" below). The thickness obtained directly after rolling is 7 mm for all materials. The flat grain structure elongated along the rolling direction like a pancake is characteristic of W plates manufactured by powder metallurgy and rolling. Many sub-grains are observed inside the grains defined by high-angle grain boundaries.

The rod material is manufactured by powder metallurgy and forging, followed by a final heat treatment at 900°C for 20 minutes to relieve stress. The deformation rate of forging is divided into three classes; high level of deformation (hereinafter denoted by "H"), medium level of deformation (hereinafter denoted by "I"), and low level of deformation (hereinafter denoted by "L "). In "H", "I" and "L", the directly obtained diameters are 6, 10, and 20 mm, respectively. As the deformation ratio increases, the grains elongate along the axial direction of the bar and grow into a needle-like shape.

Inductively coupled plasma atomic emission spectrometry (ICP-AES) and infrared absorption spectrometry (IR) were used to analyze the metals and gaseous elements, respectively. The concentrations of carbon (C), oxygen (O), and nitrogen (N) as interstitial impurities were less than 10 ppm in all materials except for the W-3%Re-1%La2O3 plate. Since such interstitial impurities are known to affect recrystallization, grain growth, and other related material properties due to segregation at grain boundaries, the reduction of these concentrations was considered during the fabrication process.

From the point of view of impurity element concentration, in the ITER shunt, it is required that the concentrations of C, O, and N in pure W should be less than 0.01% (100 ppm). Therefore, the materials in this study, except for the W-3%Re-1%La2O3 plate, meet the requirements. the concentrations of C, O, and N in the W-3%Re-1%La2O3 plate are less than 10 ppm, about 1780 ppm (including O in La2O3), and less than 10 ppm, respectively. however, since the concentration of O in this material is mainly from La2O3, the concentrations of C, O, and N in the W 3%Re-1%La2O3 plates the concentration levels of C, O, and N in the plates can be accepted as described above.

The grain size of the modified tungsten materials with the same major chemical composition decreases with increasing deformation ratios. In addition, for materials fabricated at the same deformation ratio, grain size decreases with K doping, dispersion of La2O3 particles, and Re-addition, probably due to the impediment of grain boundaries and dislocation movement by K-bubbles, La2O3 particles, and solute Re during the fabrication process. These trends apply to rolled plates and swaged rods.

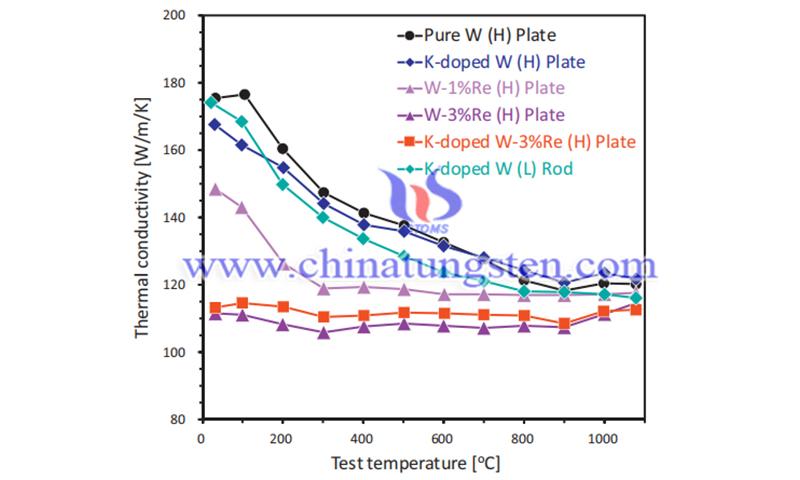

The thermal conductivity decreases with an increasing amount of Re, especially at low temperatures. Although K doping has almost no effect on the thermal conductivity of rolled plates, K-doped W(L) rods show relatively low thermal conductivity compared to pure W(H) plates. This may be due to inadequate sintering and forging conditions, resulting in porosity and elongated K-bubbles.

Reference: Nogami S, Hasegawa A, Fukuda M, et al. Mechanical properties of tungsten: recent research on modified tungsten materials in Japan[J]. Journal of Nuclear Materials, 2021, 543: 152506.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com