Multiphase Tungsten Oxide Nanocomposites

- Details

- Category: Tungsten's News

- Published on Sunday, 05 February 2023 20:38

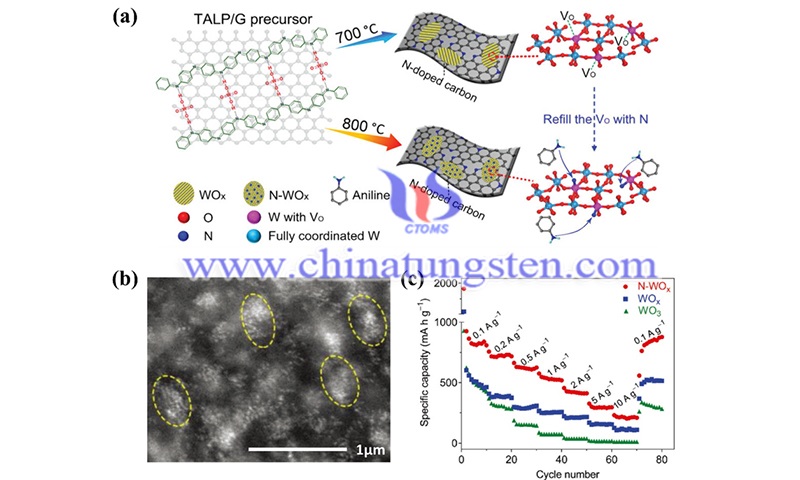

Combining WO3 with other materials into multiphase tungsten oxide nanocomposites is a straightforward approach by which better properties can be obtained in terms of good electrical conductivity, high capacitance, and good stability. These obtained composites may have the advantages of a single component and it is easier to obtain special structures that further optimize their properties. Carbon materials are often selected for their attractive electrical conductivity and low cost. In addition, they are also used as electrodes for double-layer capacitors.

The combination of double-layer capacitor materials with pseudocapacitive materials can enhance stability, capacitance, and rate performance. di et al. fabricated a chicken-hair-like carbon nanotube (CNT)@WO3 composite in which WO3 nanosheets were uniformly grown on the surface of CNT. After 8000 cycles of repeated cyclic voltammetry tests at 100 mV s-1, this composite still maintained 96.3% of the initial capacitance.

(Photo source: Han/Nanomaterials)

Shinde et al. fabricated a composite material by a two-step hydrothermal method, in which multi-walled carbon nanotubes (MWCNTs) were uniformly grown on a carbon cloth substrate and WO3 nanorods were grown on MWCNTs. The prepared three-dimensional structure has a large surface area and good structural stability. Chu et al. synthesized WO3 nanoflowers well coated with reduced graphene oxide (rGO) nanosheets. The capacities of the WO3 and WO3-rGO composites were 127 F.g-1 and 495 F.g-1, respectively, at a current density of 1 A.g-1, while the composites were up to 401 F.g-1 at a current density of 5 A.g-1. These improvements were attributed to the shorter ion diffusion paths and the three-dimensional nanostructures of the composites.

Liu et al. embedded WO3 mixed nanowires and nanoparticles in a carbon aerogel and this electrode also showed a high capacity of 609 F.g-1. The same method of dispersing WO3 nanoparticles of a selected size in carbon aerogel also yielded better results.

Transition oxide materials such as V2O5, MnO2, CuO, and TiO2 are other typical electrode materials. Due to their high capacitance and stability, they are often used to form composites with WO3 for fabrication. Shinde et al. obtained a nanostructured composite of WO3 and MnO2 with a high capacity of 540 F g-1 at 2 mA.cm-2 and good stability with an initial capacitance retention of 89% after 2000 CV tests. Yuan's research team also prepared nanostructured WO3*H2O/MnO2 composites with a high capacity of 363 F g-1 at 0.5 A.g-1.

Periasamy et al. reported the preparation of rod-shaped WO3-V2O5 composites by microwave-assisted wet chemistry method. When in KOH electrolyte, the capacity is somewhat higher than that of pure WO3. Moreover, the composite showed excellent capacity retention of 126% after 5000 long cycles and a 100% Coulomb efficiency at 5000 cycles. In addition, his team also studied WO3/TiO2 multiphase tungsten oxide nanocomposites and WO3@CuO composites.

(Photo source: Han/Nanomaterials)

In addition to carbon and transition oxide materials, organic materials, especially conducting polymers such as PANI, poly-3,4-ethylenedioxythiophene (PEDOT) and polypyrrole (PPy), are preferred for combining with WO3 due to their high conductivity, low cost and ease of fabrication. Researchers dispersed WO3 in PEDOT. The porous PEDOT matrix ensured fast ion and electron transfer, which facilitated electrochemical performance. Similarly, the researchers fabricated a WO3@PPy composite in which WO3 nanorods are the core and PPy is wrapped around WO3. shorter diffusion path lengths and greater stability were achieved due to the high electrical conductivity and specific structure of PPy.

Reference: Han W, Shi Q, Hu R. Advances in electrochemical energy devices constructed with tungsten oxide-based nanomaterials[J]. Nanomaterials, 2021, 11(3): 692.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com