Tungsten Fluoride for Electronics

- Details

- Category: Tungsten's News

- Published on Saturday, 13 March 2021 22:12

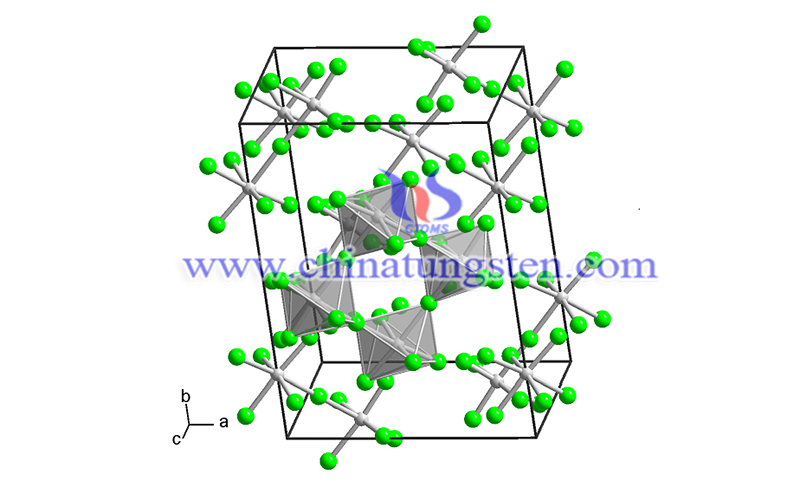

Tungsten fluoride (WF6), also known as tungsten hexafluoride, is one of the sub-industries of the industrial gas industry. It is an indispensable crucial raw material in the production process of electronics such as integrated circuits, flat display devices, semiconductor wafers, and solar cells. Among them, WF6 is currently the only stable and industrially produced variety among tungsten fluorides.

Tungsten (VI) fluoride is an inorganic compound with the formula WF6. It is a toxic, corrosive, colorless gas, with a density of about 13 g/L (roughly 11 times heavier than air. It is one of the densest known gases under standard conditions. WF6 is commonly used by the semiconductor industry to form tungsten films, through the process of chemical vapor deposition. This layer is used in a low-resistivity metallic "interconnect". It is one of seventeen known binary hexafluorides.

Tungsten hexafluoride has a molecular weight of 297.84, a boiling point of 17.5°C, and a melting point of 2.3°C. In the gas form, it is generally colorless, toxic, and corrosive. Its chemical properties are active. It can react with almost all metals except gold and platinum.

Tungsten hexafluoride is generally used as a raw material for the chemical vapor deposition (CVD) process of tungsten metal, especially tungsten disilicide (WSi2) made from it is a high-performance conductive ceramic material that can be used as large-scale wiring materials in integrated circuits. In addition, tungsten hexafluoride can also be used as raw materials for semiconductor electrodes, fluorinating agents, polymerization catalysts, and raw materials for optical materials.

The dominant application of WF6 is in the semiconductor industry, where it is widely used for depositing tungsten metal in a chemical vapor deposition process. The expansion of the industry in the 1980s and 1990s resulted in the increase of WF6 consumption, which remains at around 200 tonnes per year worldwide. Tungsten metal is attractive because of its relatively high thermal and chemical stability, as well as low resistivity (5.6 µΩ·cm) and electromigration.

WF6 is favored over related compounds, such as WCl6 or WBr6, because of its higher vapor pressure resulting in higher deposition rates. Since 1967, two WF6 deposition routes have been developed and employed, thermal decomposition and hydrogen reduction. The required WF6 gas purity is rather high and varies between 99.98% and 99.9995% depending on the application. WF6 molecules have to be split up in the CVD process. The decomposition is usually facilitated by mixing WF6 with hydrogen, silane, germane, diborane, phosphine, and related hydrogen-containing gases.

With the continuous update and iteration of electronic products, the market has a greater demand for the production capacity of raw material tungsten hexafluoride, and also put forward higher requirements for its purity, generally above 99.99%. At present, countries around the world are actively expanding the production capacity and product quality of tungsten hexafluoride and downstream applications.

Hebei Province proposed in the "Several Policies to Promote the High-quality Development of the Integrated Circuit Industry and Software Industry in the New Era" that it will rely on the 718 Institute of China Shipbuilding Industry Corporation to accelerate the development of nitrogen trifluoride, tungsten hexafluoride and other displays and special electronics for integrated circuits, to build a leading domestic industrialization base for new functional electronic materials.

It is reported that the scale of tungsten fluoride products in Hebei Province ranks first in the world. In 2020, the added value of integrated circuit manufacturing in Hebei Province will increase by 64.9% year-on-year.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com