TPU Develops New Technique to Produce Tungsten Carbide

- Details

- Category: Tungsten's News

- Published on Thursday, 21 January 2021 20:13

Tomsk Polytechnic University (TPU) scientists have developed a unique technique to produce tungsten carbide and other superhard materials. It is much simpler and more reliable than analogs. In addition, it allows using wastes containing similar materials as raw materials. The results were published in the International Journal of Refractory Metals and Hard Materials.

Tungsten carbide is a superhard material widely used in various drilling tools and other wear-resistant parts. In recent years, the potential of using the carbide as a catalyst in the production of hydrogen from water has been actively studied. Platinum, palladium, and several other expensive metals are still considered the best catalysts. However, according to the TPU research team, a relatively inexpensive nanopowder can replace them.

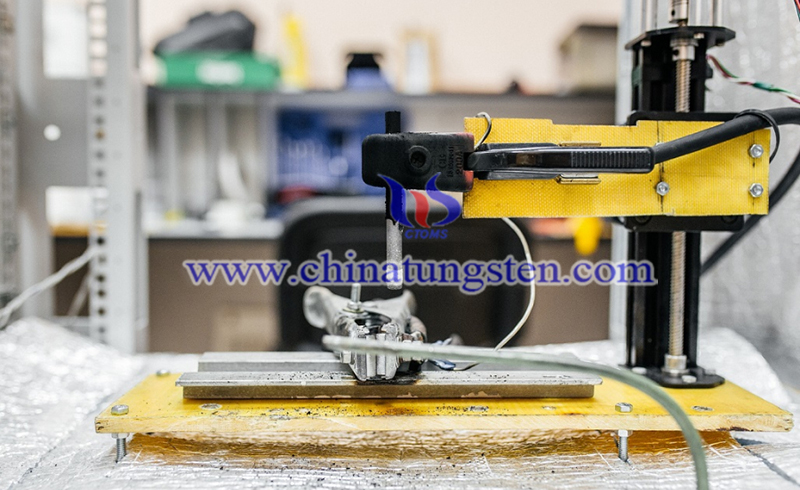

TPU scientists have created a new electric arc technique to synthesize a tungsten carbide nanopowder. This method significantly improves production technology. The new system is simpler, cheaper, more compact, efficient, and reliable than similar technologies.

Another advantage of the technique is that it can use worn-out drills, spent parts of cutters and other wastes containing tungsten carbide as source materials for the synthesis. According to the research team, it is a unique technology in terms of efficiency and costs.

TPU is a leader in the field of energy and environmental protection research. "The new technique also works for the synthesis and efficient processing of other superhard refractory materials such as titanium carbide, silicon carbide or boron carbide," the authors explain. In the future, the team plans to optimize the technique for practical implementation and expand the list of suitable waste materials

In addition, Russia's South Ural State University (National Research University) also has developed a new method of manufacturing powder composite materials based on graphite, coke, and polymer components, which will help reduce production waste in the fields of atomic energy, aviation, aerospace, metallurgy, and electronic transportation, and improve quality of electronic technology products, thereby increasing the economic efficiency of production by 30%.

Moreover, the Russian National University of Science and Technology has developed a hafnium cyanide ceramic that can withstand a high temperature of 4200 degrees Celsius. Its high temperature resistance and high hardness have been confirmed by computer modeling predictions. Asides from the TPU's excellent technology for tungsten carbide, the Russian Research University of Technology and the Institute of Biochemical Physics of the Russian Academy of Sciences have developed sodium batteries that can replace lithium-ion batteries, which can be widely used in the new generation of smart phones.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com