Baotou Huizhong Doubles Rare Earth Magnets Life

- Details

- Category: Tungsten's News

- Published on Monday, 09 November 2020 20:49

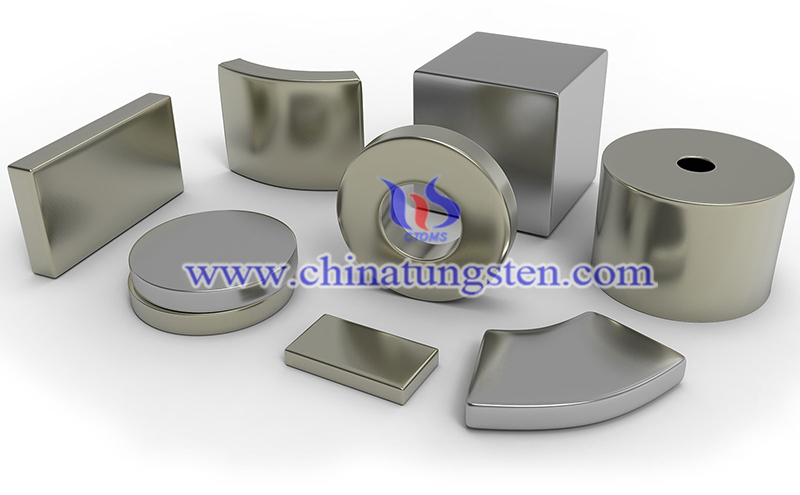

It is reported that Baotou Huizhong Magnetic Valley rare Earth Technology Co., Ltd. in Inner Mongolia uses a novel nickel and copper plating layer to form a coating on the surface of rare-earth magnets, which puts the doubles on the life of NdFeB magnets.

This technology can effectively improve the consistency and stability of rare earth magnet products, and the potential difference generated between semi-bright nickel and bright nickel can promote the surface of the magnet to change from longitudinal corrosion to lateral corrosion during the corrosion process, thereby improving the product service life. In addition, ultrasonic cleaning is added to each process of coating, which can effectively remove the surface impurities of the coating and reduce the thickness of the coating from 15 microns to 10 microns, making the product more refined and stronger.

NdFeB permanent magnet material is a permanent magnet material based on the intermetallic compound Nd2Fe14B. It has excellent magnetic properties and is widely used in electronics, electric machinery, medical equipment, toys, packaging, hardware machinery, aerospace, and other fields. Common ones are permanent magnet motors, speakers, magnetic separators, computer disk drives, magnetic resonance imaging equipment and meters.

At present, although my country's NdFeB production has formed an industrial system, the output has accounted for more than 80% of the world's total output, but it is not competitive in the field of high-end NdFeB products production, and has become a constraint on the development of the magnetic material industry. bottleneck. The main reason is that the electroplating quality of the NdFeB surface in China does not meet the requirements of high-end applications, which restricts its application in high-end products.

As we all know, the chemical properties of REEs are relatively active. Without the surface coating technology, extending the rare earth terminal industry chain is an empty talk. Therefore, the industry has long condensed the consensus of no electroplating is not high-end.

Since the beginning of this year, Baotou Huizhong Magnetic Valley relies on the key platform of the new material industry base in the rare earth high-tech zone, and has invested a lot of funds to independently research and innovate to build two high-end NdFeB high-end electroplating automatic production lines, and gather a group of experienced Iron-boron electroplating engineer, and cooperated with Inner Mongolia Autonomous Region Rare Earth Product Quality Supervision and Inspection Institute to complete the NdFeB electroplating coating inspection room, which played an active role in improving the quality of electroplating products.

It is reported that the new magnet surface coating technology of Baotou Huizhong not only significantly improves the corrosion resistance of neodymium iron boron magnets, but also saves 80% of labor costs compared with ordinary electroplating. In addition, the salt spray time of metal surface coating can be increased by 33.3%. The new technology of coating the surface of rare earth magnets with "nickel-copper-semi-bright nickel-bright nickel" as the coating layer has laid a good foundation for the comprehensive development of China's NdFeB high-end product production field in the future.

- Rare Earth Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com