Equilibrium of Rare Earth Slag Wins International Academic Award

- Details

- Category: Tungsten's News

- Published on Monday, 13 April 2020 22:11

A research team led by Zhancheng Guo achievements high-temperature phase equilibrium of rare earth slag. Recently, the American Ceramic Society (ACerS) awards the “Thermodynamics and crystallization kinetics of REEs in CaO–SiO2–Ce2O3 system” of the ACerS Spriggs Phase Equilibria Award. The study was carried out by a team led by Prof. Guo at the State Key Laboratory of New Technologies for Iron and Steel Metallurgy.

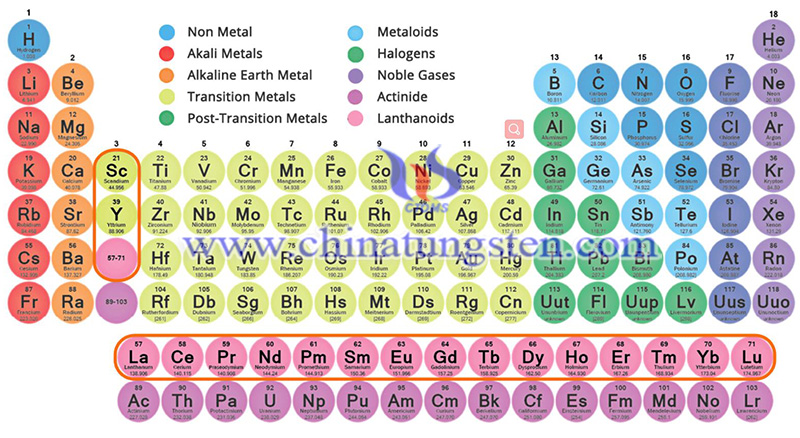

Rare earth elements (REEs) have become increasingly important as ceramic materials. The RE‐bearing slags contain massive REEs resources, whereas the lack of thermodynamic and kinetic data of REEs has brought great difficulties to efficient recovery of REEs from RE‐bearing slags and the application in ceramics.

According to the compositions of the RE‐bearing slags in industrial production, the isothermal phase equilibria of CaO–SiO2–Ce2O3 system at 1500°C and 1300°C were constructed by means of liquid‐quenching method combined with a series of analyses, which provides the thermodynamic data for the equilibria of REEs. On this basis, the crystallization behaviors of the RE phase (Ce9.33−xCax(SiO4)6O2−0.5x) was investigated, and the temperature range in which the RE phase crystallized singly in RE‐bearing slags with a selected composition was acquired.

CCT and TTT diagrams for CaO–SiO2–Ce2O3 system were established to characterize the crystallization kinetics of the RE phase, and the favorable conditions for its crystallization and growth in RE‐bearing slags were determined. In this study, the complete thermodynamic and kinetic basic data of REEs in CaO–SiO2–Ce2O3 system are provided for RE‐bearing slags.

Rare earth metals and compounds are important raw materials for high-performance materials. They normally coexist with iron ore, making the separation, and extraction difficult. Traditionally, acid-base wet separation is used for extraction, with the long process, low yield, and heavy pollution. To this end, Professor Zhancheng Guo's team took Baiyun Ebo rare earth symbiotic iron ore resources as a blueprint for research and focused on the development of high-temperature reduction ironmaking-rare earth smelting crystallization-supergravity separation and enrichment of short process resources and efficient use of clean process technology.

To realize the ultra-gravity separation and enrichment of rare earth components in rare earth slag equilibrium, it is necessary to clarify the mineral phase reconstruction process of high-temperature crystallization. However, the current literature does not have a high-temperature phase diagram, nor does it have a rare earth slag mineral phase structure and the thermodynamic data.

The research team systematically studied the crystallization process of CaO-SiO2-Ce2O3 ternary basic rare earth slag equilibrium, clarified the mineral phase structure of rare earth crystals, and filled the field of thermodynamics and phase structure. It also provides an important scientific basis for the separation and extraction of rare earth components and rare earth glass-ceramics. At present, the research achievements are granted with technical invention patents.

- Rare Earth Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com