Gold-doped Yttrium-substrated Tungsten Oxide Composite Gas Sensing Material

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 August 2019 13:29

Tungsten oxynitride NOx gas is one of the culprits in destroying the ecological environment on which humans depend. According to medical data, short-term exposure to NOx gas may cause respiratory diseases, such as airway inflammation in healthy people, and aggravate the condition of people with asthma. If exposed to NOx for a long time, it may cause pulmonary edema and even death.

The main sources of nitrogen oxides are fossil fuel combustion, energy production, and transportation. In order to be able to monitor the living environment of toxic and harmful gases in an instant and effective manner, there is an urgent need for a gas sensitive detector that can detect the type and concentration of gas.

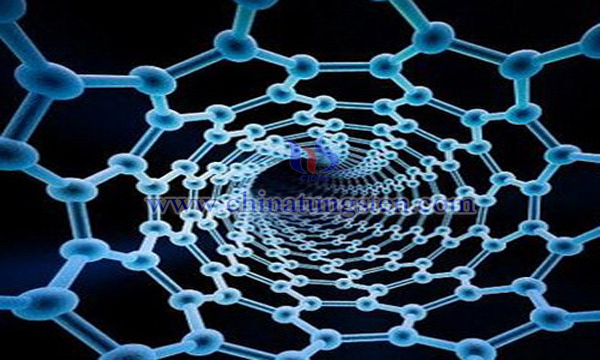

Nanostructured metal oxide gas sensitive sensors have attracted the attention of the academic community and the industrial and commercial circles due to their low power consumption and high performance. Among them, tungsten oxide is a wide band gap N-type metal oxide semiconductor, and it has been reported that it has good selectivity and sensitivity for the detection of nitrogen oxide gases such as NO and NO2. However, like most metal oxide semiconductors, tungsten oxide has a higher operating temperature, and scientists have been working on reducing the operating temperature of gas sensing materials.

Studies have shown that ruthenium-based porous ruthenium is a new type of gas-sensitive material with great potential for pore size, pore depth and porosity. With porous ruthenium as the negative-carrying metal tungsten oxide, its special microstructure can obtain a large specific surface area and can provide an effective channel for gas diffusion, which is an excellent choice for improving gas sensitivity. Recently, some scholars have developed a gold-doped porous yttrium-substrated tungsten oxide nanorod composite gas-sensitive material, including the preparation process as follows:

(1) Cleaning of the substrate

P-type single-sided polished single crystal ruthenium substrate is immersed in a mixture of concentrated sulfuric acid and hydrogen peroxide for 30-50 minutes, then immersed in a mixture of hydrofluoric acid and deionized water for 20-40 min, then separately Ultrasonic cleaning in acetone and ethanol for 10-20 minutes to remove oil stains, organic impurities and surface oxide layer on the surface of the ruthenium substrate, and finally put the ruthenium substrate into absolute ethanol for use;

(2) Preparation of porous tantalum

A porous tantalum layer was prepared on the polished surface of the single crystal tantalum sheet of step (1) by double-channel electrochemical etching using an electrolyte having a quality concentration of 40% hydrofluoric acid and a mass concentration of 40% dimethylformamide The composition has a volume ratio of 1:2. The average pore size and thickness of the porous tantalum are changed by changing the current density and the etching time at room temperature without using light, and the applied current density is 50-80 mA/cm2, and the etching time is 5. ~10min;

(3) Gold doping

The porous crucible prepared in the step (2) was placed in a vacuum chamber of a SBC-12 small ion sputtering apparatus, and a gold target having a quality purity of 99.99% was used, and the sputtering working pressure was 5 Pa, and the sputtering time was 10 s. A gold film is deposited.

(4) Preparation of seed solution

Dissolve sodium tungstate in 100 ml of deionized water, dissolve it all with a magnetic stirrer, then add dilute hydrochloric acid dropwise until no more white precipitate is formed. Then, the mixture is allowed to stand for 1 to 3 hours, and the supernatant is poured off. Then, the precipitate of the bottom layer is centrifuged by a low-speed centrifuge, and the precipitate is dissolved in hydrogen peroxide to form a yellow transparent seed solution having a concentration of 0.5-1 M;

(5) Preparation of seed layer

The seed solution prepared in the step (4) is spin-coated on the gold-doped porous tantalum prepared in the step (3), and then placed in a muffle furnace for annealing treatment, and the annealing temperature is 600-700 ° C, and the holding time is maintained. 2h, the heating rate is 2 ~ 10 ° C / min;

(6) Preparation of porous yttrium-substrated tungsten oxide nanorod composite gas sensing material by hydrothermal method

First, configure the reaction solution, weigh 4.13 ~ 8.25g sodium tungstate, use a magnetic stirrer to dissolve all of it in 25ml of deionized water, then adjust the pH of the reaction solution with dilute hydrochloric acid, then dilute the solution to 250ml, then add the appropriate amount The oxalic acid adjusts the pH of the solution, and then removes 60 ml of the prepared reaction solution into a polytetrafluoroethylene liner of a 100 ml hydrothermal reaction vessel, and adds 0.45 to 0.9 g of NaCl, and then attaches a seed layer to the (5). The porous crucible substrate is inserted into the sample holder and placed in the inner liner. Finally, the reaction kettle is placed in a constant temperature drying oven and reacted at 180 ° C for 2 h;

(7) Cleaning of porous tantalum substrate after hydrothermal reaction

The porous ruthenium substrate after the hydrothermal reaction in the step (6) is repeatedly washed with deionized water and absolute ethanol, and then dried in a vacuum oven at 60 to 80 ° C for 8 to 10 hours to obtain a final material.

Neglecting the price of precious metals, gold-doped porous bismuth-based tungsten oxide nanorod composite gas sensing materials have a large specific surface area and gas diffusion channels and a large surface activity, which can provide a large number of adsorption sites and diffusion channels, thereby facilitating the overcoming. Based on the high working temperature of tungsten oxide nanostructured gas sensing materials, it has important research value in improving the gas sensing performance of gas sensitive detectors.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com