Spherical Tungsten Powder Production Methods - 1/2

- Details

- Category: Tungsten Information

- Published on Monday, 17 June 2019 15:00

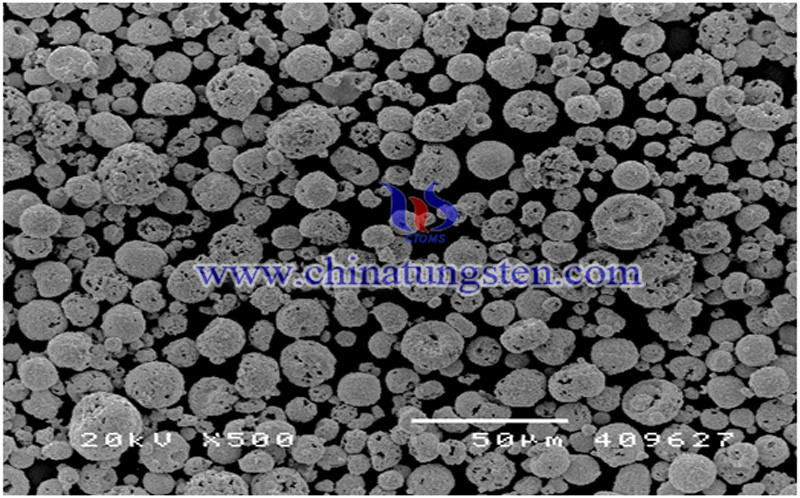

Spherical tungsten powder’s particle size for producing cemented carbide has been changing smaller of the past 20 years. As the fine-grained cemented carbide tungsten powder can significantly improve the hardness and strength of the alloy.

At the same time, because the morphology of tungsten powder will have a great influence on the properties of tungsten, the dense regular spherical tungsten powder not only has good fluidity, but also has high bulk density and small sintering shrinkage, and can obtain the ideal microstructure of tungsten material. As a result, people's interest in the control of tungsten powder morphology is increasing. Spherical tungsten powder has become an important direction in the research of tungsten powder. People dedicate on finding more effective method on producing spherical tungsten powder.

Tungstate hydrogen reduction method.

The molecular structure of the self-reducing tungstate (ART) contains an amine group such as N2H5+, NH2CH2CH2NH3+, and CH3NH3+, which generates a large amount of reducing gas upon thermal decomposition, and releases a large amount of heat, resulting in an amine tungstate having both self-reducing type as well as self-compulsibility, it can get a reduced decomposition product having a fine particle size and a narrow particle size distribution, obtained a spherical tungsten powder having agglomerated particle size of <0.5 μm and a single particle of about 20 nm by using blue tungsten oxide obtained by thermal decomposition of reduced tungstate (ART).

The method has a significant effect on the grain size refinement of tungsten powder, and can obtain spherical tungsten powder, but there are problems exist, such as high production cost, many processes, low metal yield and disposal of waste liquid, etc., which limits the usage of this method in industry.

Tungsten-hydrogen halide reduction method

The process for producing spherical tungsten powder by reducing tungsten oxide by hydrogen generally requires a large amount of hydrogen leading high cost on production. Therefore, domestic and other overseas pay much attention on preparation of spherical tungsten powder by the hydrogen halide reduction method. There have been many researches. The tungsten halide is generally WCl6, and WF6 is also used. Tungsten and tungsten waste chlorinated into tungsten hexachloride directly, and ultrafine spherical tungsten powder having a purity of >99.9% and a particle size of 0.02-0.1 μm by hydrogen halide reduction.

The main characteristics of the tungsten powder prepared by the halogenation method are high purity, fine particles, uniform particle size, spherical particles and high thermal stability. However, since tungsten powder is prepared by reduction of tungsten halogenated hydrogen, a highly corrosive hydrogen halide gas is involved in the reaction, it will cause environmental pollution and corrode production equipment, so this method is rarely used at present. There are another two spherical tungsten powder methods introduced in another article.

Spherical Tungsten Powder Production Methods - 2/2

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com