Tungsten Alloy Gas Filled Detector

- Details

- Category: Tungsten Information

- Published on Thursday, 21 May 2015 18:15

- Hits: 981

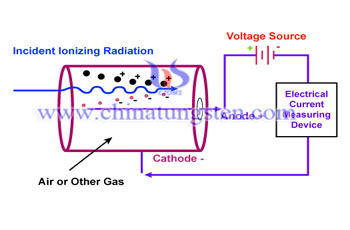

Tungsten alloy gas filled detector’s instrument works on the principle that as radiation passes through air or a specific gas, ionization of the molecules in the air occur. When a high voltage is placed between two areas of the gas filled space, the positive ions will be attracted to the negative side of tungsten alloy gas filled detector (the cathode which is made of tungsten alloy tube) and the free electrons will travel to the positive side (the anode). These charges are collected by the anode and cathode which then form a very small current in the wires going to tungsten alloy gas filled detector. By placing a very sensitive current measuring device between the wires from the cathode and anode, the small current is measured and displayed as a signal. The more radiation which enters the chamber, the more current is displayed by the instrument.

Many types of tungsten alloy gas-filled detectors exist, but the two most common are the ionization chamber used for measuring large amounts of radiation and the Geiger-Muller or GM detector used to measure very small amounts of radiation.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How Tungsten Alloy Ionization Chamber Works

- Details

- Category: Tungsten Information

- Published on Thursday, 21 May 2015 18:13

- Hits: 363

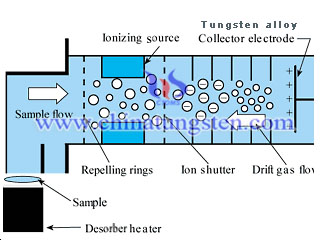

Tungsten alloy ionization chamber is an air-filled chamber with an electrically conductive inner wall and central anode and a relatively low applied voltage. When primary ion pairs are formed in the air volume, from x-ray or gamma radiation interactions in the chamber wall, the central anode collects the electrons and a small current is generated. This in turn is measured by an electrometer circuit and displayed digitally or on an analog meter.

Due to its high density and atomic mass, tungsten heavy alloy exhibits excellent absorption behaviour against electromagnetic radiation such as X-rays and gamma-radiation.A thin layer of tungsten alloy can be used on the inside surface of a cylindrical cathode to give a tungsten alloy ionization chamber having high sensitivity and outstanding resistance to the halogen gas. Furthermore, the tungsten alloy layer can be applied to the interior of a cylindrical cathode as a thin tungsten alloy foil thus omitting the necessity of electrodepositing the layer on the interior surface.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Types of Tungsten Alloy Radiation Detectors

- Details

- Category: Tungsten Information

- Published on Thursday, 21 May 2015 18:10

- Hits: 270

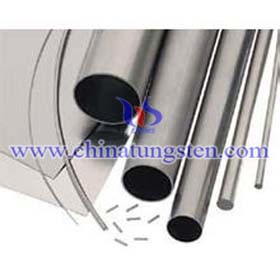

Since we cannot see, smell or taste radiation, we are dependent on instruments to indicate the presence of ionizing radiation. Radiation is energy traveling in the form of particles or waves in bundles of energy called photons.There are several types of tungsten alloy radiation detectors. Tungsten alloy radiation detectors are classified into two broad categories, Gaseous Ionization Chamber Detectors and Solid State Detectors.

Tungsten alloy gaseous ionization detectors have a gas chamber which is made of tungsten alloy. The particles to be detected are passed through the gas chamber. If the particles are of high energy they can ionize the gas atom and the gas started conducting the current. This current is measured to detect the particle or radiation.

In tungsten alloy solid state detectors, the semiconductor material, instead of gas in gaseous detector, are used as a detecting medium. A current is induced near to the p-n junction of the semiconductor material when an tungsten alloy ionizing radiation travels through these detectors.

The photograph below shows tungsten alloy materials to radiation detectors.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ultrafine Carbide Cutting Tools Development Direction

- Details

- Category: Tungsten Information

- Published on Thursday, 21 May 2015 17:56

- Hits: 299

Currently, ultrafine carbide cutting tools development direction has three main aspects: On the one hand, universal applicability grades of ultrafine carbide cutting tools are more widely used, growing versatility hand, ultrafine On the other hand, grades of ultrafine carbide cutting tools are more dedicated and better adapted to the workpiece and cutting conditions, so as to improve cutting efficiency. In addition, ultrafine carbide cutting tools development direction are also reflected in the following aspect:

In recent years, high-end CNC machine tools and basic manufacturing equipment technology major projects of national ultrafine carbide cutting tools has been systematically studied, which provides a series of ultrafine carbide cutting tools substrate material for the domestic high-end CNC machine tools and for ultra fine carbide tool high speed and efficiency of the coating of new varieties, to further promote the process of China's domestic high-end CNC tool.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

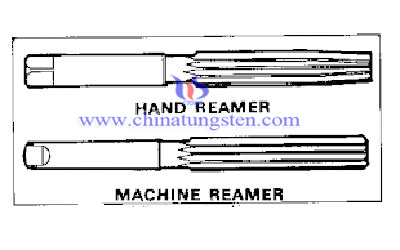

Tungsten Carbide Reamer

- Details

- Category: Tungsten Information

- Published on Thursday, 21 May 2015 17:54

- Hits: 285

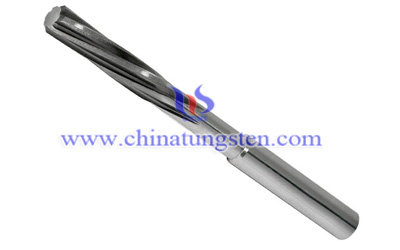

Reamer is designed as a rotary cutting tool wildly applied in metalworking. Generally, tungsten carbide reamer is build with common hard material tungsten carbide (solid or tipped).

And the tungsten carbide reamer is recommended to ream for hardened material machinery, because of the increasing forces involved in machining,as the materials are usually very brittle, requiring sightly blunt cutting edges to avoid fracture,although usually they are unaffected by the heat produced by the machining process and may actually benefit from it. The tungsten carbide reamer hardness is up to 92 Rc, which will easily outlast high-speed steels (usually by about 10:1) when reaming steel.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ultrafine Grain Carbide Cutting Tools Sintering

- Details

- Category: Tungsten Information

- Published on Thursday, 21 May 2015 17:54

- Hits: 278

Ultrafine grain carbide cutting tools sintering is an important process for the production of compact powder materials; ultrafine grain carbide cutting tools sintering can make ultrafine grain carbide cutting tools material has certain structure. Ultrafine grained WC - Co based cemented carbide cutting tools sintering an important issue is to control the grain growth and achieve full densification, and therefore should minimize the need for ultrafine grain carbide cutting tools sintering temperature and shorten the sintering time. You can grow the grain by adding inhibitors, changing WC - Co and outside the heating mode and shorten the sintering time, holding time, reduce the time and speed of WC grain growth, thereby producing ultrafine grain carbide cutting tools. Currently, for ultrafine grain WC - Co based cemented carbide sintering process maturity scale production is: vacuum sintering, vacuum sintering and hot isostatic pressing and heat treatment. Ultrafine grain carbide cutting tools sintering process optimization control, the material microstructure and mechanical properties of ultrafine grain carbide cutting tools of the pros and cons play a decisive role.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Crush Roll Grinding Dressers

- Details

- Category: Tungsten Information

- Published on Thursday, 21 May 2015 17:50

- Hits: 406

A grinding dresser is a tool used to cultivate the grinding wheel’surface, which help a grinding wheel to get back into its original shape or to make different profiles. Tungsten carbide crush roll is a tungsten carbide wheel.

Its profile is the mirror image of the desired profile of the grinding wheel. It is forced against the grinding wheel, while spinning at the same surface speed as the grinding wheel. Doing so breaks the bond between the abrasive particles on the surface of the wheel, exposing a new surface as particles fall away. One disadvantage is that the wheel profile cannot be adjusted except by replacing the roll with one having a different profile.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

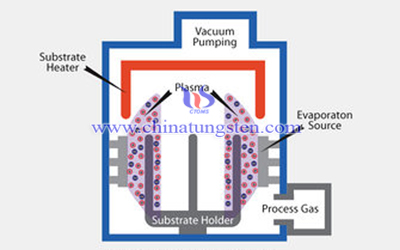

Tungsten Carbide Cutting Tools With Cathodic Arc Deposition Technique

- Details

- Category: Tungsten Information

- Published on Thursday, 21 May 2015 17:46

- Hits: 340

Cathodic arc deposition (Arc-PVD) is recognized as a physical vapor deposition technique. During the evaporation processes ,an electric arc is adopted to vaporize material from a cathode target. The vaporized material then condenses on a substrate, forming a thin film. The technique can be used to deposit metallic.

Cathodic arc deposition technique is actively used to synthesize extremely hard film to protect the surface of tungsten carbide cutting tools and extend their life significantly. A wide variety of thin hard-film, superhard coatings and nanocomposite coatings can be synthesized by this technology including TiN, TiAlN, CrN, ZrN, AlCrTiN and TiAlSiN.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Reamer Construction

- Details

- Category: Tungsten Information

- Published on Thursday, 21 May 2015 17:42

- Hits: 240

A common tungsten carbide reamer construction includes a cylindrical body that consists a set of helical cutting edges along it. Specially,every cutting edge has a slight angle, and below which there ‘s a small undercut. It is recommended that the cutting edges of reamer should have both hardness and toughness, so that ,during the usage, the tool could work functionally under the normal forces . They should only be used to remove small amounts of material. This ensures a long life for the reamer and a superior finish to the hole.

For production machine tools, the shank type is usually one of the following: a standard taper , a straight round shank to be held by a collet, or a straight round shank with a flat for a set screw, to be held by a solid toolholder. For hand tools, the shank end is usually a square drive, intended for use with the same type of wrench used to turn a tap for the cutting of screw threads.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How Tungsten Alloy Multi-Leaf Collimator Works

- Details

- Category: Tungsten Information

- Published on Wednesday, 20 May 2015 19:04

- Hits: 320

The tungsten alloy multi-leaf collimator is an important tool for radiation therapy dose delivery. It was originally used as a surrogate for tungsten alloy block field shaping and is now widely used for Intensity Modulated Radiation Therapy. For conformal radiotherapy the tungsten alloy multi-leaf collimator allows conformal shaping of the linear accelerator (LINAC) beam to match the borders of the target tumour. For intensity modulated treatments the tungsten alloy leaves of a multi-leaf collimator can be moved across the field to create Intensity Modulated Radiation Therapy distributions (tungsten alloy multi-leaf collimator's really provide a fluence modulation rather than intensity modulation).

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com