Tungsten Carbide Tool Wear During Woodcutting(1)

- Details

- Category: Tungsten Information

- Published on Monday, 25 May 2015 15:31

- Hits: 284

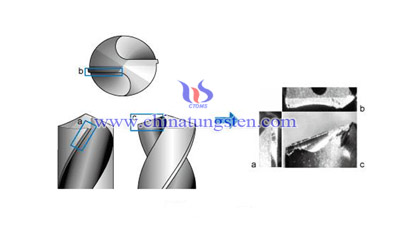

The general category of wood can be divided into three types, natural state wood, cured wood and wood-based composite materials. Within each category and between different types, the mechanical, physical, compositional and structural of wood are varied and which means each wood type displays its own unique wear characteristics. In terms of reasons caused of blunting by the tool piece and machine conditions, cutting speed and the loading as two of the important factors needed to be addressed. They make impact in factors like the machine vibrations, the type of chip formed, frictional forces and the surface finish of the wood. Depending on the cutting and wood conditions, some of the wear mechanisms may become rate controlling. For example, it has been shown that the chemical attack by the wood acids accelerate the degradation process, whereby the cobalt binder phase is preferentially removed from the hardmetal matrix thus subjecting the exposed carbide grains to increased mechanical wear.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Tool Cutting Edge’ Wear Shortcomings

- Details

- Category: Tungsten Information

- Published on Monday, 25 May 2015 15:22

- Hits: 285

Regarded to the shortcomings of the tungsten carbide tool cutting edges’ wear , it could be cataloged as, a reduction in the surface quality finish, increase in jaggedness of cutting tool edges, loss of dimensional accuracy of the wood and an increase in power consumption .

Studying tungsten carbide tool wear however, can be complicated for several reasons,

• The wear process cannot be directly observed during cutting

• Quantitative data for individual wear mechanisms are not available

• More than one mechanism may operate under similar conditions

• Synergistic interaction between different mechanisms may exist

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Tool Wear During Woodcutting

- Details

- Category: Tungsten Information

- Published on Monday, 25 May 2015 15:16

- Hits: 316

Tungsten carbide tool wear during woodcutting is complicated for two reasons, the multicomponent wood’s nature and the nature of the cutting process itself.

The tungsten carbide tools are wildly applied to woodcutting processes, which are known to be one of the most wear resistant tool materials. However, their exceptional wear resistance is adversely affected due to the combined presence of corrosive wood extractives and the abrasive wear experienced during machining. The degradation mechanisms which develop during the cutting process have been shown to be system dependent, i.e. on in the type of wood that is being cut and in the cutting tool and machine conditions being used.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Deep Cryogenic Treatment

- Details

- Category: Tungsten Information

- Published on Monday, 25 May 2015 15:12

- Hits: 364

Deep cryogenic treatment has been wildly recognized as a method of increasing the tool life span of different cutting tool materials, although hardly known about the mechanism behind it.

Up to now, there is only few detailed studies touched upon to the cryogenic treatment of tool steels. However, tungsten carbide cutting tools are now in common use in industry. From the results of primarily reports and analyses the differences in tool performance between cryogenically treated and untreated tungsten carbide tool inserts during the high-speed milling of medium carbon steel, in addition to dry cutting, machining with coolant was also tested, it can be seen that cryogenically treated tools exhibit better tool wear resistance than untreated ones. Also, it is evident that the application of coolant during cutting helps to reduce tool wear experienced by the cryogenically treated tools even further. In addition, cryogenically treated tools are found to perform best under a particular set of cutting conditions.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tools Lifetime

- Details

- Category: Tungsten Information

- Published on Monday, 25 May 2015 14:22

- Hits: 294

There are several factors related to a variety of wear processes, which could affect the lifetime of tungsten carbide cutting tools. It includes the loading, the cutting speeds and the movement of the chip over the tool face.

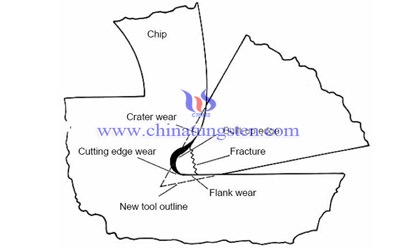

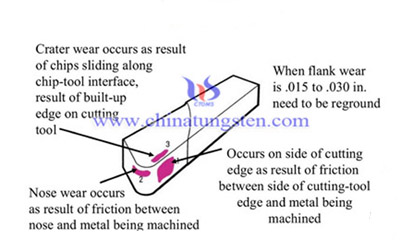

The cutting tool environment may feature high localized temperatures which may lead to thermal cracking and high stresses. The tool may also be subjected to cyclic impact loading during interrupted cutting. It shows some of the different types of wear which may be experienced during the cutting process. Along the rake face, the chip motion and high normal stresses can cause crater wear. Along the clearance surface, the tool motion and normal stresses increase the contact area between the tool and the work-piece and produce flank wear. Cutting edge wear is caused by the combined effect of the above two wear types and is the place where the dominant damage mechanisms occur in woodcutting. The response of the tool in this region generally indicates its performance and lifetime.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Friday, 22 May 2015 18:50

- Hits: 297

Chinatungsten fine tungsten wire is used in a various number of applications where precision wire is needed.

Tungsten is remarkable for its robustness, especially the fact that it has the highest melting point of all metals and the highest tensile strength. That makes fine tungsten wire very effective. The other thing remarkable is its high density of 19.3 times of water, which comparables to that of uranium and gold. This high density also means a high absorption capacity for radioactive radiation and X-rays.

The electrical conductivity is good of tungsten wire, about 30% of copper, as well as the thermal conductivity, which is about 43% that of copper. Tungsten has the lowest coefficient of thermal expansion, and at the temperature of above 1650 °C the highest tensile strength of all metals. Tungsten has unusually low specific heat, which combined with the good thermal conductivity means that the metal heats up and cools down very quickly. That is a benefit with a fine tungsten wire.

The unique characteristics of our fine tungsten wire enable us to offer a high quality precision wire. For example this means that our precision wire is available in wire sizes as fine as 4 micron.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Advantages of Tungsten Alloy Multileaf Collimator in 3d-Planning System

- Details

- Category: Tungsten Information

- Published on Friday, 22 May 2015 18:22

- Hits: 292

Recent technological developments such as 3D planning and modern tungsten alloy linear accelerators make it possible to treat more patients with conformal radiotherapy. This can be done using traditional Cerrobend blocks to shape the beam. This method however is time consuming since a block has to be made for each individual beam. During the treatment, the room has to be entered between different beams to replace the block. Therefore, a tungsten alloy multileaf collimator (MLC) was retrofitted on linear accelerator. This tungsten alloy multileaf collimator has 3 major advantages :

1、There is no need to make Cerrobend blocks.

2、There is no need to enter the treatment room between different beams.

3、There is more freedom of movement, since there is no tray hanging under the machine head.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Micro-Multileaf Collimator with Tungsten Leaves

- Details

- Category: Tungsten Information

- Published on Friday, 22 May 2015 18:19

- Hits: 308

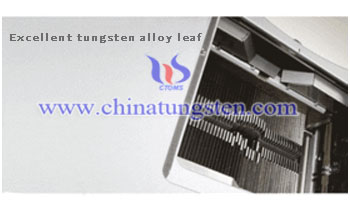

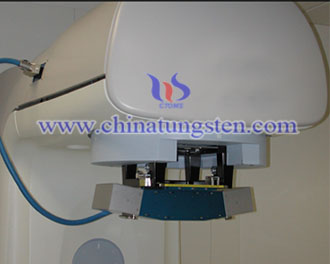

The dynamic micro-multileaf collimator (μMLC) provided by 3D Line, which consists of the μMLC and its controller as well as an associated planning system called Ergo++. A specific feature is the gantry sensor, which is integrated into the linac’s gantry and allows the system to work independently of the type or manufacturer of the linac (i.e., compatible with all accelerators on the market worldwide).

TheμMLC is double-focusing and has 24 pairs of 3.27 mm to 2.88 mm wide tungsten leaves. The tungsten leaves have a constant width of 4.7 mm, resulting in a maximum field size of 11.2 × 11cm². The prototype consisted of only 16 tungsten leaf pairs with a constant width of 3.6 mm, making it different from the μMLC.

The photograph below shows μMLC be attached to a linear accelerator.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Density of Tungsten Alloy Multileaf Collimator

- Details

- Category: Tungsten Information

- Published on Friday, 22 May 2015 18:17

- Hits: 268

The average transmission is sensitive to the physical density of the multileaf collimator(MLC). Since in order to make it machinable the be pure tungsten with density of 19.3 g/cm3 will give erroneous results for the calculated transmission. Tungsten material is 90%–95% tungsten plus alloying elements and may vary in density within the range 17–18 g/cm3. In practice, short of dismantling tungsten alloy multi-leaf collimator the tungsten alloy density can be determined for a particular tungsten alloy multi-leaf collimator by matching the calculated direct transmission to the measured direct transmission. Thus, the density becomes the only free parameter in the calculation. To match the measured direct transmission of 1.48% required an assumed tungsten alloy multi-leaf collimator physical density of 17.7 g/cm3. With the density and transmission values for tungsten alloy multi-leaf collimator suggests that variations in the average material density, and consequently the transmission, could be significant among individual tungsten alloy multi-leaf collimators.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Leaf in 80 Leaves Multileaf Collimator

- Details

- Category: Tungsten Information

- Published on Friday, 22 May 2015 18:14

- Hits: 307

One of the complications in calculating the overall transmission of the leaf bank is in accurately accounting for the complex leaf shape. The individual tungsten alloy leaves have a projected nominal width of 1 cm at isocenter 100 cm" and a physical thickness of 6.13 cm at their thickest point. The tungsten alloy leaves of the multiLeaf collimator(MLC) are single focused, i.e., the sides are shaped to converge at the source but each tip is rounded in the vertical direction in order to present an approximately constant penumbra at the isocenter plane. The radius of curvature at the center of the tungsten alloy leaf profile is 8 cm. The remainder of the tip profile is defined by two lines, each being tangent to the circular arc and at an 11.3°angle to the vertical.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com