Tungsten Carbide Cutting Tools Lifetime

- Details

- Category: Tungsten Information

- Published on Monday, 25 May 2015 14:22

There are several factors related to a variety of wear processes, which could affect the lifetime of tungsten carbide cutting tools. It includes the loading, the cutting speeds and the movement of the chip over the tool face.

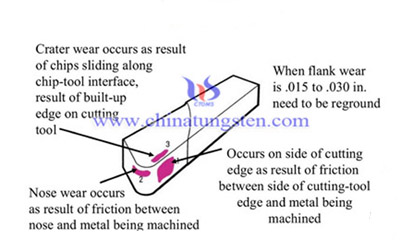

The cutting tool environment may feature high localized temperatures which may lead to thermal cracking and high stresses. The tool may also be subjected to cyclic impact loading during interrupted cutting. It shows some of the different types of wear which may be experienced during the cutting process. Along the rake face, the chip motion and high normal stresses can cause crater wear. Along the clearance surface, the tool motion and normal stresses increase the contact area between the tool and the work-piece and produce flank wear. Cutting edge wear is caused by the combined effect of the above two wear types and is the place where the dominant damage mechanisms occur in woodcutting. The response of the tool in this region generally indicates its performance and lifetime.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com