Ammonium Paratungstate Preparing Coarse Spherical Tungsten Powder (Ⅰ)

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 17:43

- Written by Cristina

- Hits: 387

Tungsten is being widely applied in the modern science and industry, especially tungsten alloy, tungsten carbide and other tungsten heavy alloy which is of high wear resistance and high corrosion resistance. Among which coarse spherical tungsten powder is an important material for preparing coarse tungsten carbide powder. Coarse spherical tungsten powder is of higher density and hardness which is widely applied in mining tools, oil drills, cutting tools, etc.

Nowadays the main tungsten powder preparing method is calcinating ammonium paratungstate into blue tungsten oxide or yellow tungsten oxide and then process through hydrogen reduction. Tungsten powder prepared by this method is of regular multi crystal and grain size is between 2-5um. In 1980s, adding alkali metal salts in tungsten oxide and process mid-temperature reduction method will enlarge the grain size of tungsten powder. Adding Na and Li together will maximize the property of tungsten powder.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate Preparing Coarse Spherical Tungsten Powder Affecting Factors

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 17:42

- Written by Cristina

- Hits: 361

Ammonium paratungstate preparing coarse spherical tungsten powder affecting factors are listed as below.

1.Adding NaCl and Li2CO3 will affect the grain size of ammonium paratungstate. Adding NaCl and LiCO3 will enlarge the grain size of ammonium paratungstate. But the effect of Li2CO3 is more apparent. The grain size can reach 60um.

2.As the reduction time prolonged, grain size of tungsten powder increases. This is because the fine tungsten oxide particles volatilize and deposit on the tungsten macro tungsten powder which increase grain size of tungsten powder gradually.

3.Adding additives. Adding alkali metal salt will enlarge the grain size of tungsten powder. When the grain size is between 45-61um, tungsten powder grain size grows rapidly. It turns out that Li will maximize the growing of tungsten powder. When the particle size reaches 100um, the growing speed slows down, the average size of tungsten powder reaches 67um which can meet the requirement in industry.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate Preparing Submicron Spherical Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 17:40

- Written by Cristina

- Hits: 370

Tungsten powder is not only the raw material of tungsten carbide, but also for tungsten alloy. It can be applied in machining, mining explore, geological drilling, construction tools, military area, etc. In order to promote the property of materials, prepare submicron spherical tungsten powder is a tendency.

Submicron spherical tungsten powder after sintering can promote the hardness and density of metal materials which improve its property. If the distribution of submicron tungsten powder is closed, materials after sintering will still be fine particles, it will affect mechanical property of materials. Methods for preparing submicron tungsten powder include ball milling, reduction under dry atmosphere, hydrogen reduction, tungsten acid reduction, etc. These methods have a lot of disadvantages such as it is of high cost and low producing efficiency which is not fit for industrial production.

Ammonium paratungstate preparing submicron spherical tungsten powder is more environmental friendly, easy to operate, the parameter is under easy control, the equipment is accessible and it is more suitable for massive production.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Optical Maser Emission from Trivalent Preseodymium in Calcium Tungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 17:39

- Written by xinyi

- Hits: 448

Coherent emission at 1.047 μ from trivalent praseodymium in calcium tungstate was observed. This emission coincides with strong infrared fluorescence at the same wavelength and was found to be stimulated mostly by absorption of blue light by the 3P0, 3P1, and 3P2 bands. The emission corresponds to a 1G4↠3H4 transition with the terminal level 377 cm−1 from the ground state. The oscillation threshold was the same at 4.2°, 20°, and 78°K. No stimulated emission was observed at room temperature. The lifetime of the metastable state 1G4 is 50×10−3 sec. A new technique used to measure the lifetime is described.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate Physical Property Affected by PH Value

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 17:37

- Written by Cristina

- Hits: 382

Average grain size and distribution of particle of ammonium paratungstate is affected by the PH value of solution. Nucleary speed and crystalline speed is affected by PH value apparently. After crystallization, the PH value is controlled between 8.0-7.8, it will reduce the nucleary amount and forming speed, the small amount of crystal nucleus can turn into large grain size steadily, also the limited PH value will make the coarse ammonium paratungstate which is distributed evenly.

Adding 10%-20% dilute hydrochloride acid into solution to the PH value 6.5-7.5, the apparent density of crystal decreases, the crystal shape is regular which makes it more convenient to prepare fine ammonium paratungstate particle. By adjusting crystallization mother liquor to the ideal PH value 6.0-8.0 and heat to above 50 degree Celsius will obtain high purity ammonium paratungstate crystal.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Diselenide Application

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 17:33

- Written by xiaoshan

- Hits: 366

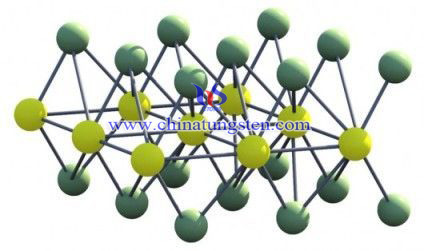

Tungsten diselenide (WSe2) conductivity is ten parts per million than the best conductivity which is diamond, it is the world's lowest conductivity material. In general, poor conductivity material (or insulator) is a porous material, but also one of the most insulation materials. Tungsten diselenide has low thermal conductivity, which is the system heat loss is not easy, so the system's energy conversion efficiency will be higher. If can full to use its insulation properties, will likely significantly increase the efficiency of energy use.

And because the main structure is composed of the upper and lower layer which is the selenium atom and the intermediate layer are tungsten atoms. This structure of WSe2 material like graphene can absorb light and the light absorption can be used to produce electricity. With further study, the researchers according to this feature of tungsten diselenide developed diodes which produce by tungsten diselenide, and this material can be applied to thin flexible solar cells.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Diselenide

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 17:32

- Written by xiaoshan

- Hits: 388

Tungsten diselenide is a gray inorganic compound, the main structure is composed of the upper and lower layer which is the selenium atom and the intermediate layer is tungsten atoms. Besides, every layer combined with van der Waals force, so tungsten diselenide in sixth metal dichalcogenides are very stable semiconductors. Its physical properties are as follows: the chemical formula: WSe2, molar mass: 341.76 • mol-1, density 9.32, CAS number: 12067-46-8.

Tungsten diselenide is often used in solar cells photovoltaic devices, while WSe2 photoelectrode in very stable under acidic and alkaline, and therefore it can be used in photovoltaic chemical barrier. Also WSe2 monolayer which is mechanical exfoliation can be used in the production of transparent photovoltaic equipment and ultra-thin LED.

Producing tungsten diselenide can put tungsten sheet in selenium vapor at high pressure and high temperature (over 800K) heating, then using sputtering deposition techniques to form hexagonal crystal on the sheet with right element proportion.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Diboride

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 17:29

- Written by xiaoshan

- Hits: 417

Tungsten diboride is a black powder, its physical properties are as follows: chemical formula: BW2, molecular weight 378.49, density 1.6 g/ml, melting point: 2670℃, having metallic conductivity, dissolved in aqua regia. Tungsten diboride should be stored in airtight, cool and dry environment. If compliance the rules will no decomposition. BW2 commonly used in the wear-resistant coating and semiconductor thin film.

Tungsten diboride synthesis methods are as follows:

1. Tungsten and boron as raw material, making two of them to full mix and grind , above 1400 ℃ heating reacted WB. And then continued reaction to obtain W2B, after cooled, pulverized to obtain the product.

2. Mixing tungsten and stoichiometric boron powder in molar ratio W:B = 2:1, sintering in a vacuum or an argon atmosphere at 1200 ~ 1300 ℃, can be obtained tungsten diboride.

3. Using solid-phase method to produce tungsten boride, where stoichiometric metal tungsten and boron as raw martial after mixed, milled, shaped, heated at above 1400 ℃ to obtain WB. To continue reaction to produce W2B, after cooled, pulverized to obtain the product.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Boride

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 17:27

- Written by xiaoshan

- Hits: 378

Tungsten boride is a black or gray hexagonal crystalline powder, its physical properties are as follows: chemical formula: WB, molecular weight: 194.65, density: 15.2g / cm3, melting point: 2660 ℃, the lattice constants a=3115nm, c=1.693nm, microhardness 3700kg / mm2, is a poorly soluble substance and having a metallic conductivity. It is often used as a wear-resistant coating and a semiconductor thin film wear parts.

The registry number of tungsten boride is as follows: CAS number: 12007-09-9, EINECS number: 234-498-8, MDL number: MFCD00049708, PubChem number: 24846684.

Producing tungsten boride can use electric furnace heated tungsten and boron to react directly then to obtain tungsten boride.

Tungsten boride synthesis method is as follows:

1. Tungsten and boron as raw material, making two of them to full mix and grind , above 1400 ℃ heating reacted WB.

2. Take 1mol tungsten and 1mol boron powder in a vacuum or in an argon atmosphere set in 1200 ~ 1300 ℃ sintering, available WB.

3. Using solid-phase method to produce tungsten boride, where stoichiometric metal tungsten and boron as raw martial after mixed, milled, shaped, heated at above 1400 ℃ to obtain WB.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Grown‐In Dislocations in Calcium Tungstate Crystals Pulled from the Melt

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 17:26

- Written by xinyi

- Hits: 388

Scheelite is a calcium tungstate mineral with the chemical formula CaWO4. It is an important ore of tungsten. Well-formed crystals are sought by collectors and are occasionally fashioned into gemstones when suitably free of flaws.

Etch pits on (001) surfaces of calcium tungstate crystals, formed on treatment with hot dilute solutions of hydrochloric acid, were identified to be dislocationetch pits. The technique is able to follow the motion of dislocations during annealing by the formation of new sharp‐bottomed pits adjacent to flat‐bottomed pits at the initial dislocation positions. Inclusions, both solid and gaseous, are an important source of dislocations in crystals of calcium tungstate grown from the melt.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com