Defect Analysis of Tungsten Contacts

- Details

- Category: Tungsten Information

- Published on Thursday, 16 July 2015 13:44

- Written by Yahong

- Hits: 404

Defect analysis of tungsten contacts is an important part to examine the microstructure. According to the standards and regulations related to tungsten contacts, and the material microstructure to check the quality of products is good or bad, that is, according to the distribution of its microstructure to largely determine the defect type and its size finally check whether they meet the requirements of the relevant standards of the product specification.

The defect types of tungsten contacts including unevenly distributed organization, porous holes, pores, bubbling, delaminating cracks, squeezing cracks, inclusions, purity of tungsten contacts material or the particle size and morphology of tungsten powder, etc.. There may be a problem of the production process, the reason is complex, and it should be comprehensively analyzed and resolved.

Microstructure analysis is one way to test the quality of metal materials, which adopt the principle of quantitative metallography.

Defect types and sizes of products materials is related to production processes and others, so, analyze the cause of the defect phenomenon can provide reference for improving product quality.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Contacts--- Adding Silver, Copper or Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Thursday, 16 July 2015 13:42

- Written by Yahong

- Hits: 495

Refractory metals tungsten and molybdenum own high hardness, high boiling point, high melting point, wear resistance, anti-welding resistance and other excellent properties, silver and copper own a good thermal conductivity and good electrical conductivity and other excellent performance, tungsten carbide can improve the anti-welding properties of tungsten contacts material and arc erosion resistance properties. Therefore, adding an appropriate amount of silver, copper or tungsten carbide, etc. can greatly improve the performance of the tungsten contacts.

Normally, the preparation process of silver tungsten contacts, copper tungsten contacts and silver tungsten carbide contacts is that: infiltration sintering process. The steps of process is shown as follows: First, pressing tungsten powder and tungsten carbide powder, molding it, and then sintering them, so that tungsten or tungsten carbide can form a porous skeleton, and then immersing molten copper or silver in porous skeleton, copper or silver will soak in skeleton pores due to the capillary action of tungsten or tungsten carbide, thus silver tungsten, copper tungsten or silver tungsten carbide contacts material with high density are available, and for silver tungsten, copper tungsten or silver tungsten carbide contacts with less content of tungsten or tungsten carbide can adopt mixing powder and sintering method.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Cracks on the Surfaces of Silver Tungsten Carbide Contacts

- Details

- Category: Tungsten Information

- Published on Thursday, 16 July 2015 13:40

- Written by Yahong

- Hits: 453

Silver tungsten carbide contacts material, in which the silver having good thermal conductivity and electrical conductivity, good oxidation resistance and good processing performance, etc., and tungsten carbide having the advantages of improving their anti-welding resistance and arc erosion resistance performance and so on.

After galvanic corrosion, the surfaces of silver tungsten carbide contacts will have cracks, its composition is not evenly distributed, you can see the loose structure of their melt layer surface, and compared to the previous experiment, the silver content is significantly reduced, contacts surfaces also did not find holes and gas eruptions pits, what suggesting that silver drip splash does not occur in the high-temperature smelting process, among which is the reason for the cracks that the lack of silver result in the loose structure. Certainly, this does not explain that the higher of the silver content can prevent cracks. Studies have shown that if the silver content is too high, it is more easily lead to large silver shedding phenomenon. Therefore, the silver content should be controlled in a certain proportion, which can reduce drip splashes and prevent cracks.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Features of Tungsten Contacts Prepared by Mechanical Alloying Method

- Details

- Category: Tungsten Information

- Published on Thursday, 16 July 2015 13:38

- Written by Yahong

- Hits: 474

Mechanical alloying method is an effective method to compound fine crystalline alloy powder material. For example, titanium aluminum alloys was required to use this method to form crystals, its most important feature is easier to obtain nano-crystalline organization, but its compactness is not good and its forming is more difficult, besides, the rapid cooling method can not get titanium aluminum alloy products.

Tungsten contacts prepared by mechanical alloying method have the following features:

1. With dispersion strengthening phase and fine, uniform microstructure;

2. The production process is simpler and more economical;

3. Improve the electrical and mechanical properties of tungsten contacts;

4. Prepare supersaturated solid solution, so immiscible tungsten contact material can be an alloying system;

5. Prepare nano contact materials with good performance;

6. Prepare refractory metal, metal oxide-based and other series of contact materials.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Using Situation of Calcium Tungstate and Calcium Molybdate

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 18:25

- Written by xinyi

- Hits: 403

The interest in CaWO4 and CaMoO4 has been driven by the fact that these compounds have especially attractive properties for a variety of optical applications (phosphors, laser hosts, scintillators). Recently, CaWO4 was implemented in the CRESST dark matter search, enabling discrimination between electron and nuclei recoils. Different types of interaction events can be identified by simultaneously measuring a combination of phonon and scintillation signals from cryogenic phonon-scintillation detectors (CPSD) operating at milli-kelvin temperatures. This technique offers high sensitivity and the unique advantage of background identification, which is crucially important for experimental searches for rare events.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

A Study of Single Phase Formation, Scintillation and Optical Properties of Scheelite Calcium Tungstate Powders and High Optical Quality Single Crystal Minirods-II

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 18:20

- Written by xinyi

- Hits: 431

For their approved use in scintillating applications, solid-state optoelectronic devices, lasers and optical fibers-like components, scheelite-type photonic crystals have attracted much interest and materials like scheelite CaWO4 have been synthesized in the last years by a diversity of methods including Pechini, polymeric precursor, co-precipitation, solvothermal, Czochralski, and microemulsion-mediated hydrothermal. However, scheelites obtained by these routes show serious problems like off-stoichiometry in any case and undesirable optical quality and scintillating properties in single crystals.

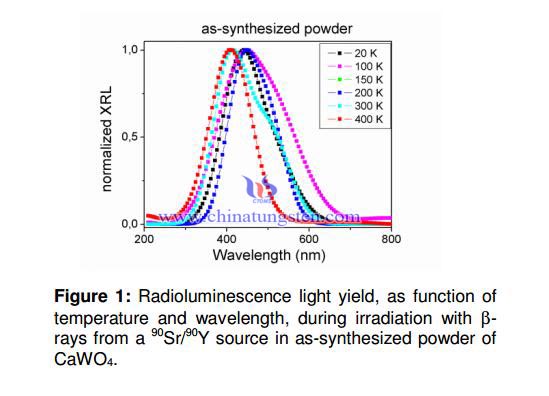

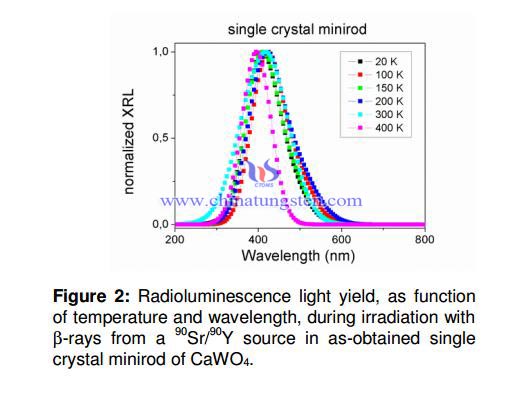

In this work, powders and single crystal minirods of scheelite CaWO4 were obtained by the methods of solid state reaction and laser heated pedestal growth, respectively, and an investigation has been made of their composition, scintillating and optical properties as revealed by X-ray diffraction (XRD), radioluminescence (RL) and optical absorption (OA) measurements.

We have found single phase CaWO4 in both as-obtained powders and single crystals, and wellbehaved optical and scintillating properties. Enhanced scintillating properties in single crystal samples were evidenced, with single or double RL peaks between 400 nm and 500 nm, with sources of β-ray or X-ray, respectively. Also, a decrease of the RL light yield with the temperature increase was observed in all the samples. A shift of the RL peak was also observed with the temperature increase.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

A Study of Single Phase Formation, Scintillation and Optical Properties of Scheelite Calcium Tungstate Powders and High Optical Quality Single Crystal Minirods-I

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 18:13

- Written by xinyi

- Hits: 332

Powders and high optical quality single crystal minirods of stoichiometric scheelite CaWO4 have been prepared by solid state reaction and floating zone methods, respectively, and their single phase formation, optical and scintillating properties have been evaluated by X-ray diffraction, optical absorption and radioluminescence measurements. All obtained results indicate that every sample is stoichiometric, while scintillation measurements reveal radioluminescence peaks at about 420 nm, 440 nm and 490 nm depending on the source of irradiation used. The single crystal samples exhibit higher radioluminescence light yield.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Phosphorescence of Calcium Tungstate Induced by X-rays

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 18:01

- Written by xinyi

- Hits: 412

The rate of decay of a very phosphorescent sample of calcium tungstate was determined photographically and found to fit the empirical equation of Becquerel, <i>I</i><sup>-x</sup> = <i>a</i>+<i>bt</i>, within the experimental error, from thirty seconds to five minutes after the exposure to x-rays. The phosphorescence of this sample could not be detected photographically more than 50 hours after the exposure of 300 milliampere-seconds at a distance of 30 cm from the target. Under the same conditions the phosphorescence of normal calcium tungstate disappeared in one minute. The intensity of the phosphorescence was found to be closely proportional to the product of the intensity of the x-rays and the time of exposure up to a limiting value, beyond which increased exposure caused a negligible increase in the phosphorescence. In general, these properties are quite similar to those of the “phosphors” of Lenard and others.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Luminescence Spectrum of Calcium Tungstate According to The Configuration Coordinate Model

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 17:46

- Written by xinyi

- Hits: 346

The configuration coordinate model has been used to calculate the luminescence band of CaWO4 at various temperatures. The force constant kg of the harmonic vibration in the ground state has been computed from the vibrational Raman spectrum of WO4/2~; the result is kg = 5.8 × 105dyne/cm. The force constant ke for the excited state, deduced from the temperature dependence of the width at half the maximum intensity of the emission band, iske = 1.5 × 105 dyne/cm. In order to obtain satisfactory agreement between theory and experiment we have to assume the variation in interatomic distance on excitation to be 0.20 Å which is in accordance with the analogous quantity of OsO4 where a calculation from spectroscopical data yields an expansion of 0.15 Å.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate Preparing Coarse Spherical Tungsten Powder(Ⅱ)

- Details

- Category: Tungsten Information

- Published on Wednesday, 15 July 2015 17:44

- Written by Cristina

- Hits: 367

Coarse and spherical tungsten powders are prepared by wet hydrogen reduction. Ammonium tungstate solutions with the additives of Li, Na and K alkali metal salts are used as raw materials. The effects of the type and content of the alkali metal salts as well as reduction time on the microstructure, chemical composition, phase composition and particle size of ammonium paratungstate and coarse tungsten powders are investigated by scanning electronic microscopy, energy dispersive spectroscopy, X-ray diffraction, and test sieves.

It is shown that ideal tungsten powders with good fluidity, sphericity, integrity and even distribution can be obtained by using the ammonium tungstate solution with 3g.L-1 NaCl, KCl and Li2CO3 and reducing at 1000℃ for 180 min in wet hydrogen atmosphere. The average particle size of the obtained tungsten powders is 67um, the maximum particle size is 150 um, the biggest loose density is 13.41g.cm-3, and the best powder flowability is 9s for 50g tungsten powders.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com