Ge-Doped Decoloration Technology of Zinc Tungstate

- Details

- Category: Tungsten Information

- Published on Friday, 17 July 2015 17:18

- Written by xiaoshan

- Hits: 399

Zinc tungstate is often used in Ge-doped decoloration technology, zinc tungsten single crystal Ge-doped decoloration technology belonging tungstate crystal production series areas. This technology generally doping Sb2O3 or Bi2O3 or silver as the toner, but the common deficiency is not drawn out of the large size of colorless crystals.

After the studies found, using GeO2 as doped material, when the weight ratio of ZnO:WO3:GeO2 is 1:1-X:X, X between 0.05% to 0.1%, the pulling rate in 1 ~ 3mm/h, rotation rate at 20 ~ 30 rev/min, the cooling rate of after growth at 150~200 ℃/ h can be achieved large ZnWO4 colorless crystals. Besides light-emitting properties slightly better than the ZnWO4, energy resolution up to about 12.9%.

And when preparing zinc tungstate crystal use Nb2O5 as doped material, the total weight ratio of between it and ZnWO4 is 2 × 10 ~ 1 × 10, the pulling rate at 3 ~ 6mm/h, rotation rate at 20~30 rev/min, the cooling rate after growth at 40~60 ℃/h, to obtain a colorless crystal large zinc tungsten, but the light-emitting properties is no different with zinc tungsten, the energy resolution up to 13 % to 14%.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

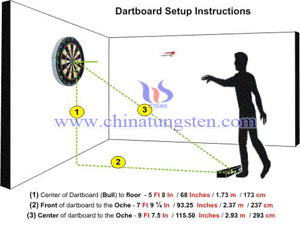

What is the correct Dartboard Setup in tungsten darts game?

- Details

- Category: Tungsten Information

- Published on Friday, 17 July 2015 17:17

- Written by yingying

- Hits: 460

Are you thinking about setting up a dart board in one of your rooms? If so, then there are a lot different considerations that you need to make like the Dart Board Height and the Dartboard Distance before start with your dartboard setup. There are some specific things that you can do to make sure that your dart board is placed in a location that is safe and fun for you to play darts. Here are a few tips that may help you in placing your dart board in the correct location.

It's important that you think very carefully about where you are going to place your dart board. You need to carefully consider a location where the dart board can be positioned flat against the wall. You also want to make sure that the dart board has enough space around it so that an aimless dart does not damage anything surrounding the board that might be expensive and that the wall is high enough to reach the correct Dart Board Height. You also want to make sure that there are no doorways in the vicinity, because you don't want to accidentally hit someone who happens to be walking through the door. So, you need to make sure that your dartboard setup is in a low traffic area so that you do not hurt someone.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

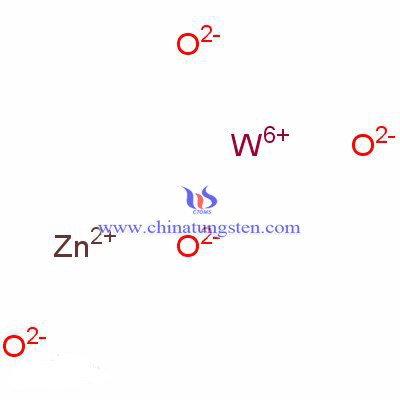

Zinc Tungstate

- Details

- Category: Tungsten Information

- Published on Friday, 17 July 2015 17:15

- Written by xiaoshan

- Hits: 380

Zinc tungstate is a white powder, also known as tungsten zinc oxide, which is stable at normal temperature and pressure. Its chemical formula is ZnWO4 and molecular weight is 313.23. In addition, it has a certain irritation, so when during the operation the worker should to take some certain protective measures, such as protective glasses, gloves and protective clothing. Zinc tungstate, usually is not harmful to water, but if there is no permission of relevant government departments, it can not be discharged into the surrounding environment. There are some related systems numbers of ZnWO4 which are as following: CAS registry number: 13597-56-3, EINECS number: 297-053-6. Besides it should be sealed and stored at somewhere has room temperaturecool dry and ventilated, but avoid light, fire and high temperatures.

Zinc tungstate is often used in Ge-doped decoloration technology, zinc tungsten single crystal Ge-doped decoloration technology belonging tungstate crystal production series areas. This technology generally doping Sb2O3 or Bi2O3 or silver as the toner, but the common deficiency is not drawn out of the large size of colorless crystals.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Calcium and Cadmium Tungstate as Scintillation Counter Crystals for Gamma‐Ray Detection

- Details

- Category: Tungsten Information

- Published on Friday, 17 July 2015 17:14

- Written by xinyi

- Hits: 347

The high density, transparency, and chemical inertness of calcium and cadmium tungstates, together with their reasonable luminescent efficiencies when stimulated with high energy radiation, strongly suggest their use as phosphors in scintillation counters for gamma-ray detection. Some of the properties of these crystals are reported and compared with anthracene. It is shown that with proper design, the total anode current produced by a given source is several times greater with the tungstates than with anthracene, although the latter has a more favorable pulse size distribution. Cadmium tungstate has a zero temperature coefficient of luminescence up to 40°C and shows no afterglow after exposure to intense radiation.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Calcium Tungstate—IV: The Theory of Coupled Substitution

- Details

- Category: Tungsten Information

- Published on Friday, 17 July 2015 17:12

- Written by xinyi

- Hits: 370

A theory is developed for the coupled substitution e.g., of Nd3+ and Na+ in Ca2+ sites in the scheelite (CaWO4) lattice. Allowance is made for Schottky defect formation.

The results fit the CaWO4: Nd system up to 2 % Nd, the CaWO4: Nd: Na system up to 15 % Na and 5 % Nd, and the CaWO4: Nd: K system up to 8 % K and 2% Nd.

Equilibrium constants resulting from the theory give the vacancy concentrations in O and Ca sites as 0.054 % each and the free energy of formation of a pair of vacancies as 55 kcal or 2.4 eV, all in pure CaWO4 in air at the melting point.

Energies are also obtained for the various other substitution arrangements. For exactly balanced substitution of one Na+ for each Nd3+ in the crystal, it is necessary to use 4.05 Na for each Nd in the melt. This also results in the minimum number of vacancies in the crystal.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Shear of Metallographic Specimen of Tungsten Contacts Materials

- Details

- Category: Tungsten Information

- Published on Friday, 17 July 2015 17:11

- Written by Yahong

- Hits: 325

Shear of metallographic specimen of tungsten contacts materials can not be arbitrarily taken, it should be in accordance with the relevant technical standards required for the implementation of the materials, such as, specimen site, amounts, data and other factors should represent the interior of the materials properties and its internal aspects of its biggest change since shearing representative and appropriate contacts materials specimen is an important step of metallurgical analysis, if you ignore the importance of this step, the test results will affect the reliability of contacts material and accuracy. Furthermore, the specimen site, direction and other factors with different research purposes should also be different.

Because the surface of the tungsten contacts materials will attach to a layer of metal or unevenly distributed layer component segregation area due to the properties of the production process, so contacts materials specimen site is:

1. Ingots. At the end of the ingots, the shear of ingots should a cross-section which is perpendicular to the die wall;

2. Wire (line) or strip. The Shear of longitudinal section and cross-section at its two ends is needed;

3. Sheet or plate. Shearing its cross-section is needed.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Chemical Etchant of Tungsten Contacts Material

- Details

- Category: Tungsten Information

- Published on Friday, 17 July 2015 17:09

- Written by Yahong

- Hits: 324

1. The chemical etchant of tungsten contacts, tungsten copper contacts, silver tungsten contacts, tungsten, nickel and copper contacts, silver-nickel contacts and others is: 50ml of ammonia or 10-30ml of hydrogen peroxide solution (30%). Highlights of use: wipe the surface of the contact material with a freshly prepared solution over 10 seconds.

2. The chemical etchant of tungsten, tungsten carbide or nickel granule in silver tungsten contacts, silver tungsten carbide contacts, copper tungsten contacts, silver-nickel contacts is: potassium ferricyanide mixture, in which,

A. K3[Fe(CN)6] 10g water 90ml

B. NaOH(KOH) 10g water 90ml

Highlights of use: A and B are mixed and wipe over the surface of the contact material.

3. The chemical etchant of tungsten granule in silver tungsten contacts and copper tungsten contacts is: potassium ferricyanide mixture, hydrochloric acid solution, in which,

A. K3[Fe(CN)6] 30g Water 70ml

B. NaOH(KOH) 10g Water 90ml

Highlights of use: A and B are mixed and wipe over the surface of the contact material.

4. The chemical etchant of pure copper, copper alloy is: ferric chloride, hydrochloric acid solution, in which,

Ferric chloride 5g

Hydrochloric acid (concentrated) 50ml

Water 50ml

Highlights of use: wipe method.

5. The chemical etchant of pure silver, copper graphite is: ferric chloride solution, in which,

Ferric chloride 10g

Water 50ml

Highlights of use: wipe method.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Metallographic Inspection Processes of Tungsten Contacts

- Details

- Category: Tungsten Information

- Published on Friday, 17 July 2015 17:07

- Written by Yahong

- Hits: 334

The metallographic inspection processes of tungsten contacts:

1. Sampling

This step is necessary to consider the characteristics and processing aspects of tungsten contacts material, and then select the location and test surface of the appropriate and representative sampling.

2. Inlaying

If the shape of the contacts material is irregular or size is not big enough, then you need to insert or holder for easy operation.

3. Coarse grinding

The purpose: to make contacts sample flat and approximately ground to a suitable shape. If it is general steel material, then you need to coarse grinding on the grinder kibble, if it is only relatively soft material, then you can use a file to polish specimens.

4. Finish grinding

The purpose: To eliminate the deep scratches of the contacts material left by coarse grinding, and make it ready for polishing. General material grinding methods can be divided into mechanical grinding and manual grinding.

5. Polishing

The purpose: This is to remove the fine cracks left by finish grinding and to make its surface as bright as a mirror, and no trace. Polishing generally is divided into chemical polishing, electrolytic polishing and mechanical polishing, among which the most commonly used is mechanical polishing.

6. Corroding

You must first carry out corroding process of contacts material so that polishing contacts can be observed under a microscope. Metallographic corroding methods include electrolysis corrosion, chemical corrosion and constant potential corrosion, among which the most commonly used, is chemical corrosion.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Defect Types of Tungsten Contacts- II

- Details

- Category: Tungsten Information

- Published on Friday, 17 July 2015 17:03

- Written by Yahong

- Hits: 358

The other defect types of tungsten contacts can be shown as follows:

6. The squeezing crack

This is because tungsten contacts have been existed or gathered porous holes before extrusion, which resulting in the formation of cracks under pressure during the extrusion process.

7. The silver belt or strap

In silver tungsten contacts or copper tungsten contacts, because during the pre-sintering process, there are cracks in porous skeleton, and silver or copper will penetrate along the cracks at the time of infiltration sintering, thereby forming a silver belt or strap.

8. The purity of tungsten contacts material

9. The particle size and morphology of tungsten powder

10. The production process for each procedure, etc.

Therefore, in the analysis of the defect types of tungsten contacts material, it should be combined with a variety of factors to determine the causes and resolve them, in order to obtain a good quality of contacts.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Dart Rules For KillersⅡ

- Details

- Category: Tungsten Information

- Published on Friday, 17 July 2015 17:02

- Written by yingying

- Hits: 352

you hit your own double after you have become a killer you do kill yourself! Each time a kill occurs, one life is erased from that player's tallies. Once the player has no lives left that player is out of the game. Play continues until the only one player has any life left.

Variations of this game can be played to adjust to the players' level. You could use all triples for stronger players or require a double bull to become a killer. For weaker players, use the thin inner wedge of the number. On occasion, I have had several average players and one "I never picked up a dart before" kind of person. So what I do is set that the "new player" only has to hit the thin or thick single wedge to become a killer or kill while the rest of us have to hit doubles. With all the combinations available it's easy to balance the play to be fun for everyone.

Strategy: There really isn't much strategy to this game but I can offer a couple of tips. First, try not to hit a number right next to some one else. If you do, you will get accidental kills from people who were trying to kill the other player. Also players will tend to aim at that spot with the thought that there is more chance to kill someone if they don't yet have a favorite enemy yet.

Another tip is to try to stay neutral and to kill people evenly. If you blast someone, while ignoring other players it will be remembered for several games and that player will be out to get you.

Often the players try to take out the stronger players who have a better chance of killing them than the weaker players. This can often lead to the worst player wining the game because when the smoke clears, the stronger player will probably only has one life left. The weaker player, on the other hand, probably has all three lives left because that player was left alone. The weaker player now only has to hit one dart to win the game.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com