Tungsten Carbide Nozzle Types

- Details

- Category: Tungsten Information

- Published on Friday, 31 July 2015 18:23

- Written by xiaobin

- Hits: 334

Tungsten carbide nozzles are divided by its different shape of nozzle’s bore, while the shape will determine its blast pattern. A normal tungsten carbide nozzle always has one straight bore, limit bore or venture bore. Straight bore is the most common, which creates a sealed blast pattern for spot blasting or blast working inside. It is suitable for smaller jobs such as parts cleaning, welding fabrication, cleaning handrails, steps, grillwork, or carving stone and other materials.

Venturi bore nozzles forms a full blast pattern and accelerate grinding as much as 100% under a given pressure so that it is the best choice for larger surface to enhance the efficiency. Long venturi nozzle raises 40% velocity in productivity and saves 40% grinding compounds compared with straight bore nozzle. Wide throat nozzle is also called wide angle nozzle, which is divided into big and small droplet specifically. It is designed that a large entry and diverging entry bore. When matched with the same sized hose, they can increase 15% in productivity compared with nozzles with a smaller throat. In addition, there are some diverse angle nozzles for specific spots like bridge lattice, behind flanges, or inside pipes.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Nozzle Description

- Details

- Category: Tungsten Information

- Published on Friday, 31 July 2015 18:22

- Written by xiaobin

- Hits: 337

Tungsten carbide nozzle is made from hard materials (superhard alloy) by precision machinery, and its anti-bending strength can reach over 2300N/mm, hardness can reach over 90HRA. It is necessary that do the precise grinding and surface treatment when machining tungsten carbide nozzle, and make sure to achieve Ra0.1 of the bore roughness and the Ra0.025 of the R place of both ends. In addition, there is a scientific curvature radius design between the two entrances. This design ensures a smooth transit of the thread. Due to the overall materials processing, no elevation in the drilling bore, it is beneficial for improving the phenomenon of bending and blocking.

Tungsten carbide nozzle is sintered from straight bore and venturi bore type. Owing to its good hardness, low density and excellent wear-resisting, Tungsten carbide nozzle has been widely used in sandblasting and shooting peen equipments so that it can offer a long lifespan in optimum air and grinding materials.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The results of “Additive (Co, Ni and Zr) Effect on Ag-WC-C Contacts Experimental Procedure”

- Details

- Category: Tungsten Information

- Published on Friday, 31 July 2015 17:11

- Written by Yahong

- Hits: 385

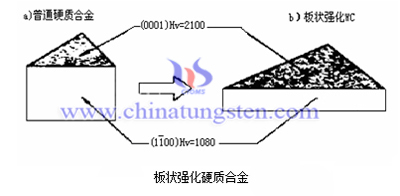

Materials: plate-grain tungsten carbide, silver powder and additives (Co, Ni and Zr)

Preparation method: chemical coating process, sintering and re-pressing process

The experimental results: Upon examination, the prepared plate-like WC grain of AgWC12C3 contacts own the characteristics of directional arrangement. The adding of Additives (Co powder, Ni powder and Zr powder) significantly improving the interface bonding strength and wettablity of components among Ag, WC and C, and improve the sintering and mechanical properties of the material. AgWC12C3 contacts (silver-based contact materials) hardness, density and conductivity, etc. are significantly improved over AgWC12C3 contacts (spherical tungsten carbide) prepared by conventional powder metallurgy method are much better.

After testing, AgWC12C3 contacts manufactured in" Additive (Co, Ni and Zr) Effect on Ag-WC-C Contacts Experimental Procedure", whose average relative density of 99.6%, average hardness HB = 70.6kg / Mm2, average resistivity Ρ = 2.84μΩ • cm; If use the grain direction which is parallel to the plate-like WC crystal grains direction as the electrical contacts, its contacts conductivity will be higher, its anti-arc resistance property will be stronger, and it will have a longer life. Whereas the AgWC12C3 contacts prepared by mechanical mixing powder method, whose raw material is spherical tungsten carbide powder, its relative density is only 95.9-98.9%, hardness HB = 56.1-60.2kg / Mm2, resistivity Ρ = 3.18-3.40μΩ • cm.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Additive (Co, Ni and Zr) Effect on Ag-WC-C Contacts Experimental Procedure -Ⅱ

- Details

- Category: Tungsten Information

- Published on Friday, 31 July 2015 17:09

- Written by Yahong

- Hits: 338

Additive (Co, Ni and Zr) effect on Ag-WC-C contacts experimental procedure -Ⅱis shown as following:

Sample 2

Preparation process is substantially the same to sample 1, except that:

Silver is 49.7g; additive Co powder is 0.3 g;

Sintering 4.5 hours (in the sintering furnace at a temperature of 840 ℃), and finally re-pressing at a pressure of 13.5T / Cm2.

Sample 3

Preparation process is substantially the same to sample 1, except that:

Silver is 49.7g; additive Ni powder is 0.3 g;

Sintering 4.5 hours (in the sintering furnace at a temperature of 800 ℃), and finally re- pressing at a pressure of 16.5T / Cm2.

Sample 3

Preparation process is substantially the same to sample 1, except that:

Silver, 49.7g; additive Zr powder, 0.3 g;

Sintering 5 hours (in a sintering furnace temperature at 750 ℃), and finally re- pressing at a pressure of 14T / Cm2.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Additive (Co, Ni and Zr) Effect on Ag-WC-C Contacts Experimental Procedure-Ⅰ

- Details

- Category: Tungsten Information

- Published on Friday, 31 July 2015 17:07

- Written by Yahong

- Hits: 313

Additive (Co, Ni and Zr) effect on Ag-WC-C contacts experimental procedure is shown as below:

Experimental Materials:

(1) Silver powder, 51g

(2) A plate-like WC powder, 7.2g, its average length is 2-5um, its length-thickness ratio is 3-5

(3) Graphite powder, 1.44g, its average particle size is 2 ~ 50μm, its density is 2.2 ~ 2.3g / cm³

Experimental procedure:

Sample 1

1. Weigh the above materials and sieve them (100 mesh stainless steel mesh screen), then add WC powder, graphite powder to the blender, mix and stir to get mixing powder;

2. Prepare silver nitrate solution (dissolve silver powder fully in concentrated nitric acid);

3. Pour the silver nitrate solution into the reaction vessel, complex with ammonia until its PH = 10; add the mixing powder to the reaction vessel and stir it, to obtain a composite powder;

4. Keep stirring and pour reductant hydrazine hydrate in a way of liquid spraying through an atomization device into the reaction vessel, until it response adequately;

5. Clean composite powders with distilled water to neutral, dry then (in the dryer, at the temperature below 90 ℃), to obtain dry coating silver (plate- shape grain tungsten carbide, graphite) complex powder;

6. Cold-press the coating composite powder, and then under H2 atmosphere, sintering 3 hours (in the sintering furnace, at a temperature of 840 ℃), and finally re-press at a pressure of 15T / Cm2 for AgWC12C3 contacts .

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Discussion Ag-WC-C Contacts from Tungsten Carbide Powder

- Details

- Category: Tungsten Information

- Published on Friday, 31 July 2015 17:01

- Written by Yahong

- Hits: 320

Preparation of Ag-WC-C contacts needs to use tungsten carbide powder and other powder as its raw material; the following is part knowledge of tungsten carbide powder.

Cubic WC1-X is used to represents W - C is a non-stoichiometric composition;

What represent W-C stoichiometric composition are: the hexagonal WC, the hexagonal W2C. At room temperature, only the Six-Party WC is stable.

The hexagonal WC cell structure is staggered triangular prismatic shape, which is Non-Centro symmetric structure, its lattice constant a = 2.916 × 10-10m (hexagonal, a = b), c = 2.844 × 10-10m. Nowadays, the main appliance of tungsten carbide is used to manufacture high-quality carbide, and it can also be used in contact material, metal coating, metal ceramics and other fields.

The lattice constant also known as the lattice parameters, referring to the length of a side of the unit cell, which have a direct contact with the combination of atoms, and it is an important basic parameters of the crystal structure, whose change may reflect changes of the composition in the crystal and status of the force.

Studies have shown that the mechanical property of tungsten carbide is not only related to its composition but the sintering process, and is also closely related to its microscopic crystalline structure. Currently, the preparations methods of tungsten carbide powder methods are:

(1) Tungsten powder is first prepared, and then adds carbon to make it carbonized to obtain tungsten carbide powder;

(2) Preparation of tungsten carbide powder from tungsten carbide compound.

However, both methods have common drawback is that both need a high carbonization temperature (1300 ~ 2000 ℃), the preparation process is complex, and it is costly, what is more, tungsten carbide prepared by this way is usually near-spherical. Using this kind of tungsten carbide powder to prepare plate-like strengthening tungsten carbide powder, there is a need to adopt a special sintering process to make the WC grain growth into a plate, and its orientation is not ideal.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Replace Tungsten Dart Flight

- Details

- Category: Tungsten Information

- Published on Friday, 31 July 2015 16:46

- Written by yingying

- Hits: 292

The flights on your tungsten darts are the most vulnerable part, and because of that they will need to be replace often. Let’s learn how to replace tungsten dart flight!

Instructions:

Choose your dart flights. Standard dart flights are pretty wide, which effects the movement of the dart. They straighten the dart out in the air, which makes them good beginner flights. They are also good for people who like to lob their darts rather than throw them straight with a lot of force. Narrower flights are good for short shaft darts and for aggressive throwers. Check the reference below for more info on dart flights.

Pull the old flight straight out of the shaft of your dart. You can save it in your dart case as a spare, or simply throw it out.

Inspect the dart shaft. If it is cracked or bent in any way, unscrew it and screw in a new shaft. Plastic shafts go bad all the time, and a new flight won't help your game if it is wobbling around in an old shaft.

Gently bend the new flight so that the planes are at right angles to each other. The flight should form two flat, intersecting planes for a total of four fins.

line up the flight with the slits on the back of the shaft. Gently push the flight into the shaft until it is all the way in.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Sharpen Tungsten Darts

- Details

- Category: Tungsten Information

- Published on Friday, 31 July 2015 16:43

- Written by yingying

- Hits: 405

Sharpening tungsten darts is a slight misnomer. You do not actually want your dart tips sharp and pointy, but rather rounded and smooth. This prevents darts from bouncing off the wires on your board, maintains a strong dart tip and protects your board. However, you do need to use a dart sharpening stone on your darts when they become flat or develop burrs. Sharpen your darts to take out any burrs that may occur and keep the darts rounded and smooth. So let’s learn how to sharpen your tungsten darts!

Instructions:

Check your dart tips for burrs. Run a nail up and down each dart tip and feel for abrasive burrs. If burrs exist, you'll need to sharpen.

Lay the steel tip in the concave section of the sharpening stone.

Slowly rotate the tip on the stone.

Check the tip to make sure that all burrs have been ground out. The tip should be smooth.

Dull the very tip of the tungsten dart. If you have sharpened the dart to a point, round it out slightly by holding the dart vertically and pressing the tip against the sharpening stone. Spin the dart in a circular motion until the tip is rounded.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Start A Tungsten Dart League

- Details

- Category: Tungsten Information

- Published on Friday, 31 July 2015 16:40

- Written by yingying

- Hits: 330

Starting a simple to run tungsten dart league can be challenging, but it can be easy if you use the proper tools. Running a tungsten dart league requires dedication every week. Tungsten dart leagues usually run for twenty-six weeks for the winter league and ten weeks for the summer league. The organizer will need to keep money deposits, score records and print out weekly leader board sheets to be delivered to each team sponsor. The amount of time spent will be determined by the amount of teams as well as how many nights a week you run the league play. Steps of starting a tungsten dart league are as following:

1.Set up an excel spreadsheet with all the teams names. The spreadsheet will have a category for the team name, wins, losses, games played, percent of wins and forfeits. Another spreadsheet will have every individual player listed with the team name, the points per dart average, then categories for six, seven, eight and nine dart out rounds. The spreadsheet also needs a column for wins, loses, hat tricks and assisted wins.

2.Set up a twenty-six or ten week schedule that says where each team plays each week. The schedules are set up so that every team plays a different team every week and then it starts the cycle over again until the season is finished. If there are an uneven number of teams, there will be a bye week.

3.Every week the visiting team to the home team will drop off the score sheet with the money from the game for that given week. The money goes to the bank for the end of the year party and prizes.

4.Enter all the information from the score sheets into the excel spreadsheets accordingly. Once this is done, the organizer will make a team standing sheet or leader board sheet that is given to each sponsoring establishment to post.

5.Steps 3 and 4 are repeated every week until the season ends.

6.At the end of the season, a bust up party is planned where food and drinks are served by using the money that was taken in during the season. This is where prizes are given out for first, second, third and forth place teams. The individual players also get a prize for best shooter and the most wins. Teams are also given a sum of money for the number of wins.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

All Fives Tungsten Dart RuleⅠ

- Details

- Category: Tungsten Information

- Published on Friday, 31 July 2015 16:38

- Written by yingying

- Hits: 379

All Fives also known as Fifty One by Fives(51 by 5’s), which is a popular tungsten dart rule.

The aim / object of the game: Is for each player to throw his/her round of three tungsten darts in such a manner, that the total score of the three darts accumulated, will always be divisible by 5. If any of the 3 tungsten darts in such a throw by the player, fall / bounces out or hits the outside number ring, then such a throw will count as score zero.

Please note these abbreviations:

Pts = Points

B = Bull

S/B = Single Bull (25 score)

D/B = Double Bull (50 score)

S20 = Single 20 (20 score)

D20 = Double 20 (40 score)

T6 = Treble 6 (18 score)

S = Single D =Double T =Treble / Triple B =Bull

The scoring works in the following manner: The total score of three darts thrown must be accumulated, and if the score is divisible by 5 then each “divisible 5” counts as 1 point.

For Example:

Darts 1st 2nd 3rd Score

Hitting 5 2 8 15 = 3 Points (15 divided by 5 = 3)

Hitting 10 D20 T5 65 = 13 Points (10+40+15=65 div. 5 = 13)

Playing the Game:

Determine who throws first by allowing each player to throw one dart “closest to the bull”. If some players are very accurate, then everyone should throw at the double bull with their least accurate hand and the player who is closest to the bull throws first, 2nd closest second and so on.

Players 1:

Throws his/her round of three darts. Let’s assume he/she hits T20 with the 1st dart, S10 with the 2nd dart, D8 with the 3rd dart. The 3 throws hit accumulated was 60(T20) + 10(S10) + 16(D8), which totals 86. 86 divided by 5 equals 17.2 which means the score accumulated in this throw of 3 darts was not divisible by “5”. Score=0

Players 2:

Throws his/her round of three darts. Let’s assume he/she hits D6 with the 1st dart, T16 with the 2nd dart, S20 with the 3rd dart. The 3 throws hit accumulated was 12(D6) + 48(T16) + 20(S20), which totals 80. 80 divided by 5 equals 16 which means the score accumulated in this throw of 3 darts was divisible by “5”. Score=16 (16 x 5 = 80)

The winner is determined by the first player who accumulated 51 Points or more.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com