A Tungsten Halogen Lamp Without Metal Stents

- Details

- Category: Tungsten Patents

- Published on Wednesday, 13 March 2013 15:18

- Hits: 2657

The utility model involves a tungsten halogen lamp without metal stents, including bulb casing, filament, lamp holder, lamp foot. In the upper end of the lamp housing on opposite sides of a connection portion extending to the bulb housing cavity lateral and twothe free end of the connecting portion bonding said filament supported located at the junction of the two connecting portions. The connecting portion is connected by filament stent and regard the connecting portion as the metal stents,so that we can replace the conventional metal molybdenum wire for the stent.

On the one hand, it can grealy reduce the cost of manufacturing Halogen and make the process of production more simpler and easier.On the other hand, it overcomes the defects of metal molybdenum wire stent affect the life of the lamp.This kind of tungsten halogen lamp is very economical and practical.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Graphite Boat And Method For Producing Tungsten Carbide By Direct Carbonization of WO3+C+H2 Using Same

- Details

- Category: Tungsten Patents

- Published on Wednesday, 13 March 2013 09:05

- Hits: 2828

Brief description of this technology:

The invention discloses a graphite boat and a method for producing tungsten carbide by directly carbonizing WO3+C+H2 with the graphite boat, where the graphite boat is combined of top and bottom cabins, and the method: putting WO3 and C mixed powders into the two cabins, and directly producing WC in a carbonization furnace ventilated by hydrogen gas.

The invention can obtain WC product with uniform size, and stable carbon content; can shorten the whole reaction time of WO3 with C and H2, increasing WC output; can reduce H2 utilization, saving production cost; and can prolong service life of the carbonization furnace.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Nitride Atomic Layer Deposition Processes

- Details

- Category: Tungsten Patents

- Published on Tuesday, 12 March 2013 09:10

- Hits: 2949

In one embodiment, a method for forming a tungsten barrier material on a substrate is provided which includes depositing a tungsten layer on a substrate during a vapor deposition process and exposing the substrate sequentially to a tungsten precursor and a nitrogen precursor to form a tungsten nitride layer on the tungsten layer. Some examples provide that the tungsten layer may be deposited by sequentially exposing the substrate to the tungsten precursor and a reducing gas (e.g., diborane or silane) during an atomic layer deposition process. The tungsten layer may have a thickness of about 50 Å or less and tungsten nitride layer may have an electrical resistivity of about 380 μΩ-cm or less. Other examples provide that a tungsten bulk layer may be deposited on the tungsten nitride layer by a chemical vapor deposition process.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

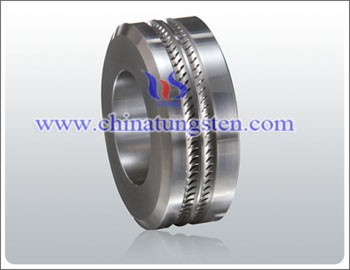

Methods of Making Tungsten Carbide-based Annular Jewelry Rings

- Details

- Category: Tungsten Patents

- Published on Tuesday, 12 March 2013 15:36

- Written by Elva

- Hits: 2840

This Study relates to a method of making a finger ring which comprises:

Providing a jewelry finger ring that defines an aperture configured and dimensioned to receive a person's finger and which comprises a sintered mixture of at least two powdered materials comprising tungsten and a binder component in a relatively lesser amount than an amount of tungsten, with the annular ring having at least one external facet.

Tungsten carbide (WC) is a very hard ceramic (second only to diamond in hardness). It is a principle component in many powder metallurgy applications and is commonly referred to simply as carbide. Tungsten powder, either in elemental form or as a compound (most commonly WC), is either used alone or mixed with other powdered substances, such as other carbides, nitrides, ceramics and/or metals. The other powdered substances are usually selected for the properties, such as color or corrosion resistance, they impart to the completed piece. A powdered metal binder such as cobalt or nickel may also be included in the mixture. The powdered mixture is then poured into a mold and pressed to form a blank which can be shaped. The blank is then heated. This "sinters" the blank into a very hard solid.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Method and Apparatus For Depositing Tungsten After Surface Treatment

- Details

- Category: Tungsten Patents

- Published on Tuesday, 12 March 2013 08:57

- Hits: 2877

Brief description of this technology:

A method and system to form a refractory metal layer over a substrate includes introduction of a reductant, such as PH3 or B2H6, followed by introduction of a tungsten containing compound, such as WF6, to form a tungsten layer. It is believed that the reductant reduces the fluorine content of the tungsten layer while improving the step coverage and resistivity of the tungsten layer. It is believed that the improved characteristics of the tungsten film are attributable to the chemical affinity between the reductants and the tungsten containing compound. The chemical affinity provides better surface mobility of the adsorbed chemical species and better reduction of WF6 at the nucleation stage of the tungsten layer.

The method can further include sequentially introducing a reductant, such as PH3 or B2H6, and a tungsten containing compound to deposit a tungsten layer. The formed tungsten layer can be used as a nucleation layer followed by bulk deposition of a tungsten layer utilizing.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com