What Is Tungsten Alloy Shielding Can?

- Details

- Category: Tungsten Information

- Published on Tuesday, 19 August 2025 16:30

- Written by Xiaoting

- Hits: 19

In today's era of rapid technological advancement, radiation has become an unavoidable part of our lives. Medical radiography is a common scenario where we encounter radiation; for instance, X-ray examinations clearly reveal the condition of human bones, aiding doctors in diagnosing fractures and lung diseases. Similarly, industrial flaw detection employs techniques like radiographic and ultrasonic testing to detect cracks or pores in components of aerospace equipment and automobiles without damaging the workpiece. However, the radiation sources used in flaw detection, such as X-rays and gamma rays, are highly radioactive. Without proper protection, operators exposed to radiation over long periods may suffer radiation damage. Thus, radiation protection is crucial, and the tungsten alloy shielding can serves as a "sturdy shield" safeguarding us from radiation harm.

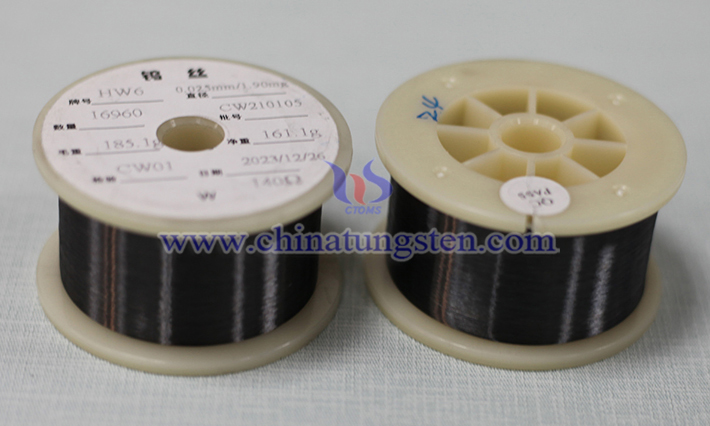

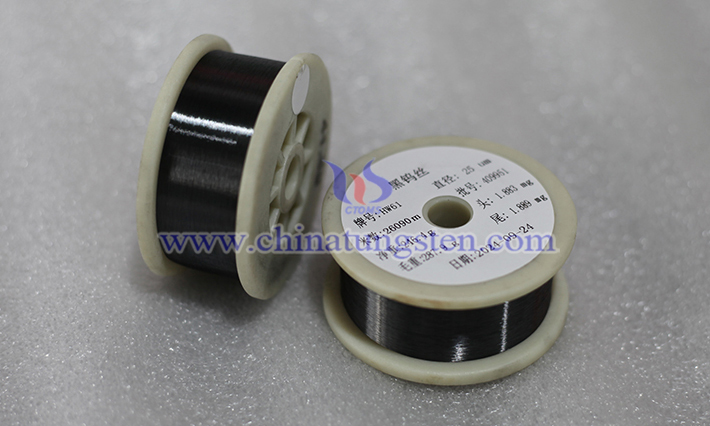

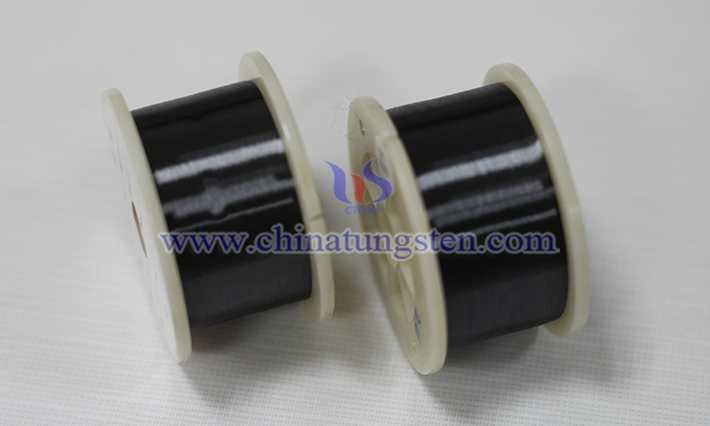

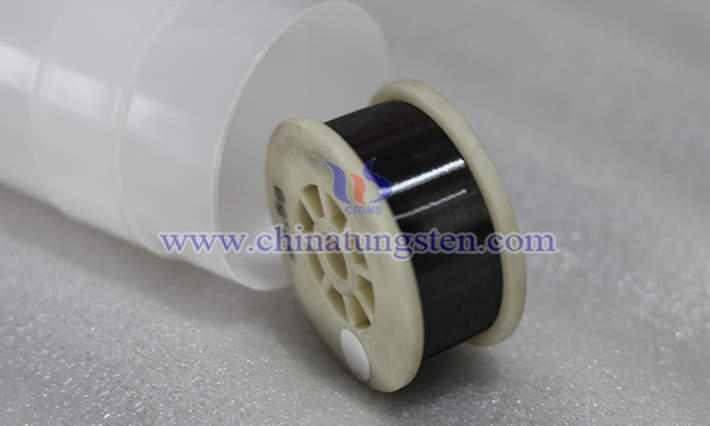

Black Tungsten Wire Applications

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 18:56

- Written by Zhenghua

- Hits: 54

Due to its high melting point, high strength, and corrosion resistance, black tungsten wire has important applications in lighting, electronics, high-temperature industrial applications, medical treatment, welding, photovoltaics, and emerging fields. Although some traditional uses have been impacted by new technologies, its irreplaceable nature in high-temperature, high-precision applications ensures continued demand.

Black Tungsten Wire Characteristics

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 18:52

- Written by Zhenghua

- Hits: 53

Due to its exceptional physical and chemical properties, black tungsten wire is widely used in lighting, electronics, photovoltaics, and high-temperature industries. As a processed product of the high-melting-point metal tungsten, tungsten wire possesses unique properties that enable it to perform exceptionally well in extreme environments. The following details its key characteristics.

The Difference Between Black Tungsten Wire and Cleaned Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 18:54

- Written by Zhenghua

- Hits: 48

The main difference between black tungsten wire and cleaned tungsten wire lies in surface treatment and appearance: black tungsten wire has a gray-black color due to the presence of graphite emulsion on its surface; cleaned tungsten wire is black tungsten wire that has been alkaline washed or electrolytically polished, resulting in a silvery-white surface with a smooth finish, making it suitable for high-precision and high-temperature environments. Each type has its own advantages depending on the application requirements.

Read more: The Difference Between Black Tungsten Wire and Cleaned Tungsten Wire

Uses of Black Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 August 2025 18:50

- Written by Zhenghua

- Hits: 48

Due to its excellent high-temperature resistance, mechanical strength, and chemical stability, black tungsten wire plays an irreplaceable role in lighting, electronics, high-temperature industries, welding, photovoltaics, medical treatment, and scientific research. The following details the main uses of black tungsten wire.

sales@chinatungsten.com

sales@chinatungsten.com