Single Action Pressing of Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Friday, 14 July 2017 18:17

Single action pressing is the earliest used powder compacting mode,cavity block and core pin hold-on,upper punch put pressue in the single direction .Besides,external friction make the top density higher than bottom and smaller the compaction diameter is, the bigger of the height it will be.

So single action pressing is more applicable to used in products which height-diameter ratio is H/D≤1 or some sleeve parts which wall thickness ratio is H/T≤3.

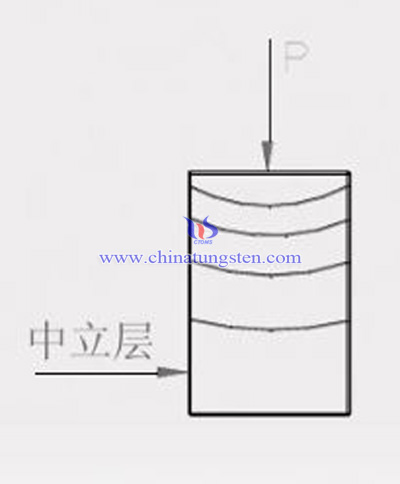

On account of the pressing process exists force of friction,the height and cross section of the compaction,density distribution is nonuniform, compaction density is different here and there.The density contour line of the nickel powder one-dimensional press cylindrical compaction

In a general way,neutral axis of the single action pressing compaction and neutrosphere is in the bottom of the compaction,(if assume that compaction is consists of innumerable longitudinal tier,on account of the cross section keep plane,it accounts for dimensions of portrait is gradual continuous changed from shorten to elongation,there must be a neutrosphere is neither cut down nor extend(unconfined and no-tension) neutrosphere is the interface of upper drawing zone and compression zone. Intersection of the neutrosphere and cross section,it known as neutral axis.)

In order to improve the nonuniform density distribution of the single action pressing compaction condition,we can adopt the following measures:

1.Improve roughness and finish of the mold walls;

2.Add lubricating medium;

3.Mold designer reduce height-diameter ratio H/D.

| Tungsten Powder Supplier: Chinatungsten Online tungsten-powder.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com