WO3/Cd2SnO4 Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Thursday, 01 September 2016 11:41

Solar radiation transferred into electrical energy which people need has become a hot research spot, to be a very promising way of replacing the power generation which will bring toxic gases and dust and other environmental pollution, like thermal power. Photocatalytic reaction is an energy source to split water into hydrogen and oxygen under sunlight at room temperature just like plant photosynthesis, the hydrogen produced can be used as fuel instead of conventional fossil fuels; moreover, the oxygen generated can effectively oxidize and degrade the harmful organisms in water.

Solar radiation transferred into electrical energy which people need has become a hot research spot, to be a very promising way of replacing the power generation which will bring toxic gases and dust and other environmental pollution, like thermal power. Photocatalytic reaction is an energy source to split water into hydrogen and oxygen under sunlight at room temperature just like plant photosynthesis, the hydrogen produced can be used as fuel instead of conventional fossil fuels; moreover, the oxygen generated can effectively oxidize and degrade the harmful organisms in water.

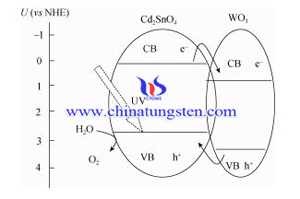

Studies have indicated that both WO3 and Cd2SnO4 are semiconductor material and can do as a photocatalyst, Cd2SnO4 has a high electrical conductivity with a narrow gap (<3eV); while, tungsten trioxide is a transition metal semiconductor with a specific N-type structure, has a high valence band potential (0.5eV) and a suitable band gap (2.7eV). However, since either of both has a relatively low photocatalytic activity of oxygen evolution as photocatalyst, but the compound semiconductor can effectively improve the photocatalytic reaction efficiency, and can improve the light-generated carriers transfer rate between different energy levels in semiconductor, and also effectively improve the quantum efficiency, thus to consider the composite of Cd2SnO4 and WO3. Experiment has taken sodium stannate, cadmium acetate and sodium tungstate as raw materials by impregnation method to get WO3/Cd2SnO4 composite photocatalyst with high photocatalytic activity for oxygen evolution which reaches to 200μmol / (g • h).

Preparation Process of WO3/Cd2SnO4 composite photocatalyst is as following:

1. Dissolve amount of sodium stannate, cadmium acetate in water and mix well according to certain molar ratio, then add the appropriate amount of sodium hydroxide solution to precipitate the unreacted transformed of Cd2+ to Cd(OH)2;

2. Filter the precipitates and washed repeatedly with water, then move into a muffle to calcine at 1000℃ for 3 hours to prepare CdO/Cd2SnO4 powder, and then remove CdO with a certain amount of dilute hydrochloric acid solution to obtain the pure Cd2SnO4;

3. Dissolve a certain amount of sodium tungstate in water, and add a small amount of hydrochloric acid to form sol, then adsorb tungstic acid onto the surface of Cd2SnO4 by impregnation, after filtration, we will get tungstic acid and Cd2SnO4 composite powders, then calcine under 600℃ to generate WO3/Cd2SnO4 composite photocatalyst.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com