Important Indicators of Tungsten Trioxide SCR Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Friday, 09 September 2016 17:45

Currently, the commonly used of denitration catalyst is the tungsten vanadium and titanium system which takes titanium dioxide as carrier, V2O5 as the main active component, WO3 as co-catalyst as a co-catalyst, that is V2O5-WO3/TiO2. Catalyst which fills in the catalytic reactor is the core of the SCR process, vanadium pentoxide (V2O5) has the highest activity in all metal oxide catalysts, and also V2O5 will oxidize sulfur dioxide to sulfur trioxide at the same time. Thus SCR processes often adds tungsten trioxide (WO3) as a co-catalyst, thereby reducing the load of V2O5 (wt%) to 1.5% or even less, maintaining the reduction of NOx reduction catalytic oxidation of sulfur dioxide on the basal activity. The additive of tungsten trioxide can improve the hydrothermal stability, and resist toxic substances of As ect. in the smoke.

Important indicators of tungsten trioxide SCR denitration catalyst are active temperature, geometrical parameters, etc., as follows:

1. Activation temperature, which is the most important indicator of tungsten trioxide SCR denitration catalyst. Because the reaction temperature not only determines the reaction rate of the reactants, but also decides the reaction activity of the catalyst. Usually the reaction temperature of V2O5-WO3/TiO2 catalyst is located between 280~420℃, if the temperature is too low, then the reaction rate is slow, and even generate side reaction which is unfavorable to NOx degradation; however, when the temperature is too high, the catalyst activity occurs microcrystalline high-temperature sintering phenomenon.

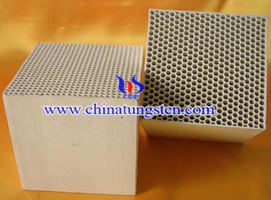

2. The geometric parameters: pitch/spacing, specific surface area, porosity and specific pore volume, mean pore size and pore size distribution.

1) Pitch/pitch SCR denitration catalyst is another important indicator, denoted P, P=d+t, where d represents the width between the two plates, t is the thickness of the plate and its size affects catalytic reaction’s pressure drop and residence time, pore clogging or not;

2) The specific surface area is the total exposed surface area per unit mass of the catalyst, which directly affects active catalyst of surface, and the porous particles can greatly increase the surface area of catalyst;

3) Porosity is the ratio of pore volume and the whole grain volume of the catalyst, which is the most direct quantitative indicator of catalyst structure, and determining the specific surface area and pore size;

4) The distribution of pores in the catalyst is very important, when most of them are closed to the average pore diameter, then the catalyst has the optimum activity.

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com