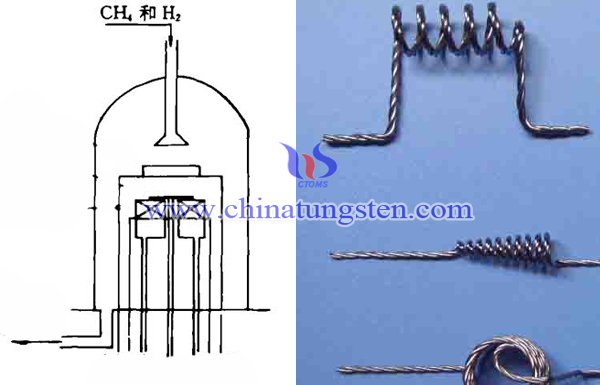

Diamond Film and Tungsten Heater

- Details

- Category: Tungsten Information

- Published on Monday, 11 July 2016 16:29

Thermal solution source of tempering wire method - spiral tungsten wire (tungsten heater). However spiral tungsten wire is susceptible to be distorted by the influence of the deposition process. Large area diamond coating requires a relatively uniform temperature field, and deformation of tungsten wire will destroy the uniformity of the temperature field in the original design. Straight tungsten wire as the heater can solve the problem of deformation of spiral tungsten wire sagging. In addition, energy density of the single straight wire is lower than the spiral wire, which can ensure a high pyrolysis energy density. Arrange pyrolysis wire by multiple process can resolve problem of closed-packed of wolfram wire, but due to the large pyrolysis current, so it requires a low-voltage high-current power supply device.

Hardness of diamond film is the highest of solid material, it can reach HV100GPa with a thermal conductivity of 20W • cm-l • K-1, which is 5 times the copper. The resistivity at room temperature is 1016Ω • cm and it can form semiconductor material by doping.

The sample substrate temperature of diamond by tempering wire chemical vapor synthesis method is greatly influenced by the temperature of the pyrolysis wire and the distance of sample substrate. Pyrolysis wire temperature, the distance between pyrolysis wire and the sample substrate and sample substrate temperature are difficult to operate simultaneously at the respective optimum parameters. So operators should use ∅0.3mm diameter tungsten wire, which can reduce sagging of wolfram wire to a minimum degree. Using the independent electric heating device can make the sample maintain a certain temperature, when the sample substrate close to the pyrolysis wire, effective amount of heat of it would radiate to the sample substrate, and it is time to adjust heating power smaller, or it is no need to heating by electric furnace and direct use the flow of cooling water to control the temperature of the sample substrate.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com