Effect of TiC in Copper-tungsten Electrodes

- Details

- Category: Tungsten Information

- Published on Friday, 09 October 2015 16:56

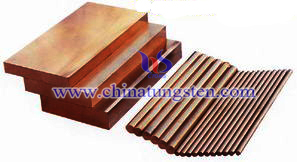

Due to the high thermal conductivity of Cu, and the better spark erosion resistance, low thermal expansion coefficient and high melting temperature of W, copper-tungsten electrodes have been widely used for machining die steel and tungsten carbide work-piece. The materials normally used in EDM electrodes are various types of copper, graphite, tungsten, brass and silver. But copper-tungsten has better properties. The low melting point of Cu reduces the resistance to electrode wear.

At high tungsten content, there is porosity in the liquid phase sintered electrode due to the insolubility between the Cu and W. This greatly impedes densification during the solution-reprecipitation stage of liquid phase sintering. Hence, this makes it necessary to introduce another material with high melting point. Materials having good electrical and thermal conductivity with a high melting point are used preferably in copper-based electrodes to resist electrode shape-loss.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com