Tungsten Carbide Cutting Tools Shock Crack

- Details

- Category: Tungsten Information

- Published on Wednesday, 27 May 2015 15:45

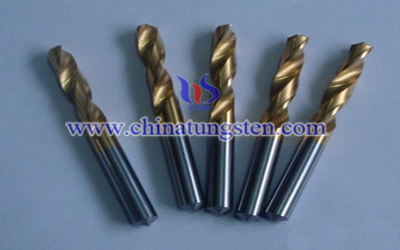

Tungsten carbide cutting tools shock crack is resulted by the grinding wheel vibration or instability which have an impact on tungsten carbide cutting tools and lead to flank shatter or chipping. Therefore, tungsten carbide cutting tools shock crack mainly caused by vibration. Measures to avoid the impact of tungsten carbide cutting tools shock crack are mainly the following two points.

1. Check whether the balance wheel is the same on both sides of the flange diameter and uniform tightening of screws, the clamping force is the same, identify problems and timely adjustments. If you can not eliminate vibration, then you want to find on the grinder other reason may be that grinder bearing damage, or grinder shaft bending. Nearby is also a need to check whether the resonance caused by external vibration sources, and if so, can be added in an appropriate amount of wood saw chips or sand grinder cavity inside, to be stable equilibrium.

2. Timely repair wheel In the grinding process of tungsten carbide cutting tools, the interaction between wheel and tungsten carbide cutting tools leads to loss of tungsten carbide cutting tools and abrasive broken off so that the gallery-shaped abrasion, grinding wheels will be distorted and blunted, cutting weakened, there will be vibration. Then we need to be trimmed wheel.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com