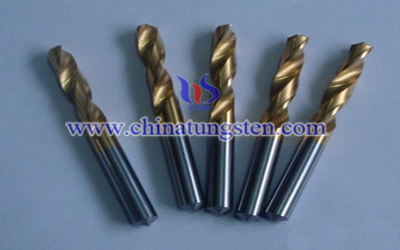

Tungsten Carbide Cutting Tools Oxidative Wear

- Details

- Category: Tungsten Information

- Published on Monday, 25 May 2015 18:26

Tungsten carbide cutting tools oxidative wear is another important manifestation of tungsten carbide cutting tools wear mechanism in the air. At 600 ° C or less, tungsten carbide cutting tools oxidative wear is not obvious, at 600 ° C or more, WC and Co tungsten carbide cutting tools begin to be oxidized within, wherein, WC is the main product of oxidation is WO3, The main product was the CO is oxidized CO3O4. At the same time, the ability to fine grain carbide cutting tools antioxidant than coarse grains of carbide cutting tools. In severe wear (3000r / min ,, 350N) cases, tungsten carbide cutting tools containing oxidation products friction surface binder phase CO generated as WO3 and COWO4, and friction product does not contain CO alloy surface is WO3 and WC . Wherein, CO is no separate oxidation products, which is due to the necessary conditions for CO oxidation during rubbing friction surfaces are brought together in a sufficient amount of CO, or can together form a W element oxide, i.e.

In nitrogen low friction coefficient of friction, wear small amount of nitrogen medium has good friction reduction, reducing tungsten carbide cutting tools oxidative wear occurs.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com