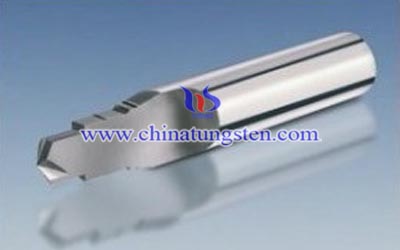

Tungsten Carbide Cutting Tool Wear Section

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 March 2015 10:09

Tungsten carbide cutting tool wear process can be divided into early wear, normal wear and rapid wear in three stages:

1. Wear the early stages

The existence of the new coating flank rough place, residual stresses and micro-cracks and other defects after tungsten carbide cutting tools, and relatively sharp cutting edge, flank a smaller area in contact with the process, the pressure stress, therefore, at this stage wear faster wear rate of less the two tools.

2. Normal wear stage

With the increase in cutting time, the new tool after run-in, the contact area between the tool and the workpiece increases, the pressure decreases, and wear changes stabilized.

3. Rapid wear stage

In rapid wear stage, surface roughness thicker, cutting force and cutting tools are rapidly increasing temperature, tool wear faster. Sharp knives entered the stage of significant signs of wear stainless steel chip color changes from normal wear stage became dark yellow blue purple.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com