Tungsten Carbide Cutting Tools Gradient Processing

- Details

- Category: Tungsten Information

- Published on Thursday, 12 February 2015 10:19

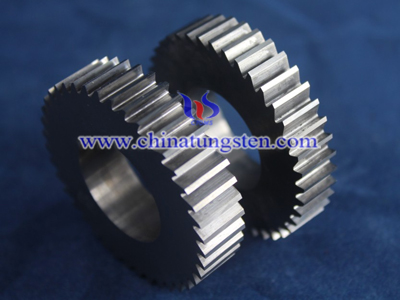

A refractory metal tungsten carbide hard metal compound and a binder made by powder metallurgy method, its hardness (HRA) is 89 to 94, much higher than the high-speed steel; at 540 ℃ hardness (HRA) 82 to 87, and the hardness of high-speed steel normal temperature (HRA83 ~ 86) fairly, but also has good chemical stability, heat resistance advantages. Tool materials currently used for a lot of variety though, the new tool materials are also emerging, but still very popular tungsten carbide tool material kind.

In order to prevent the material as a result of crack propagation due to the failure, and is favorable for obtaining a high-performance tungsten carbide cutting tools material may gradient processing, the surface area of the coated substrate formed lack toughness cubic tungsten carbides and carbonitrides of region, this region is higher than the binder content of the nominal binder content of the coating substrate; when a crack is formed in the coating extended over the area, because of their toughness, crack propagation can absorb the energy, it is possible to effectively tungsten carbide cutting tools to prevent cracks internal expansion, improve the performance of tungsten carbide cutting tools.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com