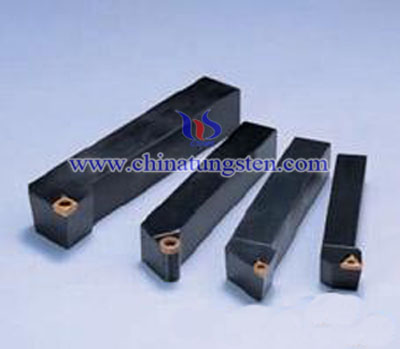

Precautions of Using Tungsten Carbide Turning Tool with Indexable Inserts

- Details

- Category: Tungsten Information

- Published on Friday, 14 November 2014 17:21

When using tungsten carbide turning tool with indexable inserts, operators should pay great attention to problems as follows:

I. Blade loosening

If blade loosening happens due to the vibration in the turning of tungsten carbide indexable inserts, operators should check whether the blade is clamped tightly or the clamping component is out of shape.

II. Abnormal noise

If there is squeak during the cutting, the reasons may be that the cutting tool is not clamped tightly; the cutting tool has seriously worn; the toolbar sticks out too far or lacks toughness; the workpiece for fixture lack toughness, and so on.

III. Spark in tool nose

If there is spark in the tool nose, the reasons may be that the cutting tool has seriously worn out; there is gap or blade tipping in the tool nose or cutting edge; the cutting speed is too high, and so on. Therefore, the cutting edge or blade then should be replaced and the cutting speed also should be adjusted.

IV. Blade surface stripping

If blade surface stripping happens during cutting, the amount of cutting fluid should be increased for those blade materials using cooling fluid, while for those high-hardness blade materials unsuitable to use cutting fluid, dry cutting should be adopted.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com