Tungsten Carbide End Mill Clamping

- Details

- Category: Tungsten Information

- Published on Friday, 24 October 2014 16:39

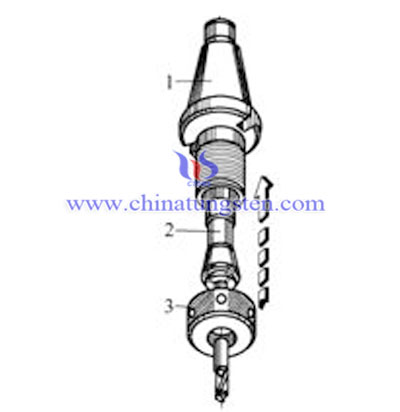

Tungsten carbide end mill in machining center normally adopts spring jacket clamping. During the milling, end mills may sometimes stretch out from toolholders or even fall off, causing the pieceworker scrapping. It is mainly because of the existing of oil slick between toolholder inner hole and the outer diameter of end mill handle, which results in the smaller clamping force. Therefore, before the end mill clamping, the end mill handle and toolholder inner hole need to be cleaned up.

However, even though the handle and the toolholder are both clean, when the end mill diameter is oversize, there could still be blade falling accidents, so when this happens, handles without gaps and the corresponding side lock method should be adopted.

The end mill being clamped may break at the edge of the toolholder during machining, and reason generally is that the toolholder has been used for a long time, resulting in a cone-shaped damage in its edge part. Therefore, the old toolholder should be replaced with a new one as soon as possible.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten?News & Tungsten Prices, 3G?Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com