How to Distinguish the Color-Coded of Lanthanum Tungsten Electrodes?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:08

In the welding industry, tungsten electrodes, a key material in precision processes like argon arc welding (TIG), play a crucial role in arc generation, stable electrical conductivity, and heat conduction. With the advancement of materials processing, welding alloys doped with rare earth elements have gradually replaced traditional products containing radioactive components.

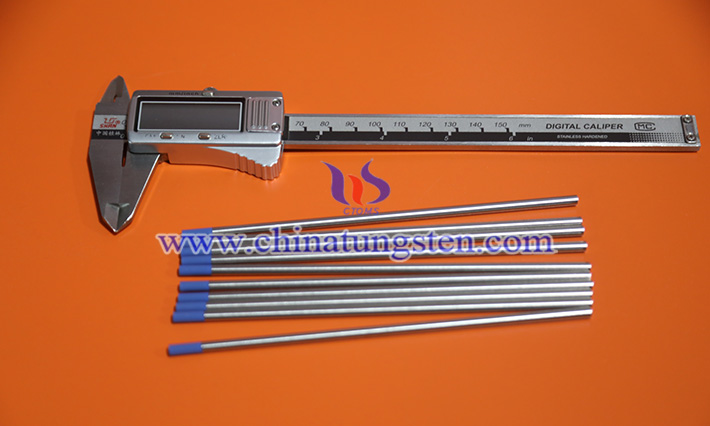

Among these, products doped with lanthanum oxide (LTO) are widely used in various industrial applications due to their excellent arc starting performance and environmental friendliness. So, how can lanthanum tungsten electrodes be accurately distinguished by color or marking when purchasing and using them?

Globally, welding electrodes are usually color-coded to distinguish different compositions and uses. This is a practice recommended by standard organizations such as the International Welding Institute (IIW) and the American Welding Society (AWS). The identification color of lanthanide products is gold or sky blue, depending on the proportion of the elements contained. By observing the color of the electrode tail, users can quickly determine which category the product belongs to.

The common types on the market currently include the following three types:

WL10: The type with lanthanum oxide content of 1.0%. Its standard identification color is black, but some manufacturers also use light blue or gray-blue as identification colors. This type of product is suitable for general welding work, especially in situations where arc stability is not required.

WL15: Contains about 1.5% lanthanum, and is identified by its gold color. It is the most widely used type at present. It is commonly used for welding stainless steel, low carbon steel and non-ferrous metals due to its good arc starting ability, thermal stability and long service life.

WL20: represents the model with a lanthanum oxide doping ratio of 2.0%, usually identified by sky blue or water blue. This type of material is suitable for high-intensity operations such as high current and continuous welding. It has stronger ablation resistance and longer service life. It is widely used in high-end manufacturing industries such as aerospace and pressure vessels.

In addition to color, some manufacturers will also print model identification on the packaging, label or even the body of the electrode, such as " WL15 " or " WLa15 ", etc. These markings can be used as auxiliary references for color identification. During storage and use, it is very important to keep the color identification clearly visible to avoid mixing different types of products, resulting in unstable welding quality or equipment damage.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com