What Is Lanthanum Tungsten Electrode?

- Details

- Category: Tungsten Information

- Published on Wednesday, 30 July 2025 16:00

In modern welding technology, non-consumable electrodes play an extremely important role in high-quality welding processes, especially in application scenarios such as tungsten inert gas welding (TIG), where the performance of electrode materials directly determines the stability, efficiency and quality of welding.

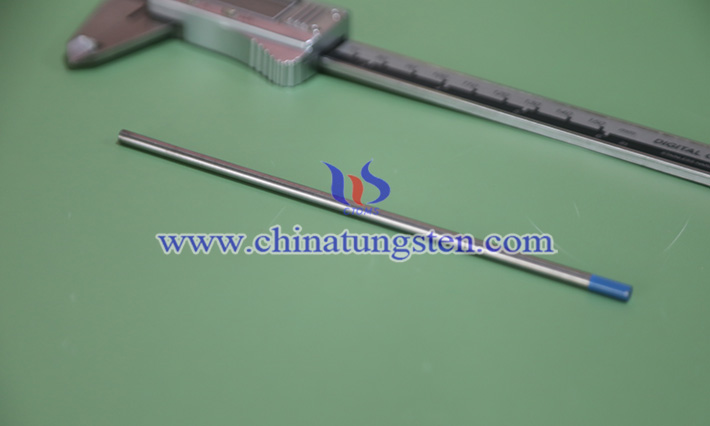

Among the many tungsten-based electrode materials, alloy products doped with rare earth elements have gradually replaced traditional materials and become the mainstream choice of the industry. One of the widely used new electrode materials is lanthanum tungsten electrode.

Adding a certain percentage of lanthanum oxide (La₂O₃) to pure tungsten, typically ranging from 1.0% to 2.0%. This modification significantly enhances the electrode's electron emission capability, enabling stable arc starting even at low currents, smoother welding, and improved arc focus. Compared to traditional thoriated tungsten electrodes containing radioactive elements, lanthanum -doped alloys not only offer superior performance but are also environmentally friendly and free of radioactive substances, better meeting the dual environmental and occupational safety requirements of today's manufacturing industry.

In practical applications, this new material shows good high temperature resistance and ablation resistance. It has low loss during welding and strong tip retention, suitable for long-term continuous use, and is particularly suitable for automated welding systems. Compared with other rare earth doping types (such as cerium, zirconium, etc.), the addition of lanthanide improves the overall performance more evenly, and shows good versatility whether used for direct current welding (DC) or alternating current welding (AC).

In addition, lanthanum tungsten electrode is particularly suitable for welding stainless steel, carbon steel, titanium alloy and some high temperature alloys. It is widely used in aerospace, pressure vessels, rail transportation, precision electronics and other fields, and is highly recognized by professional welding engineers. It performs particularly well in welding situations with low current and high stability requirements.

Common types on the market mainly include WL10 (1.0% lanthanum), WL15 (1.5% lanthanum) and WL20 (2.0% lanthanum) with different ratios. Users can choose according to specific welding requirements, current type and process parameters to obtain the best welding effect. The grinding method of this material is basically the same as that of traditional tungsten electrodes, but it has stronger anti-pollution ability and is less likely to cause contamination and deformation of the electrode end.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com