The Powder Metallurgy Technology for Tungsten Crucible

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:04

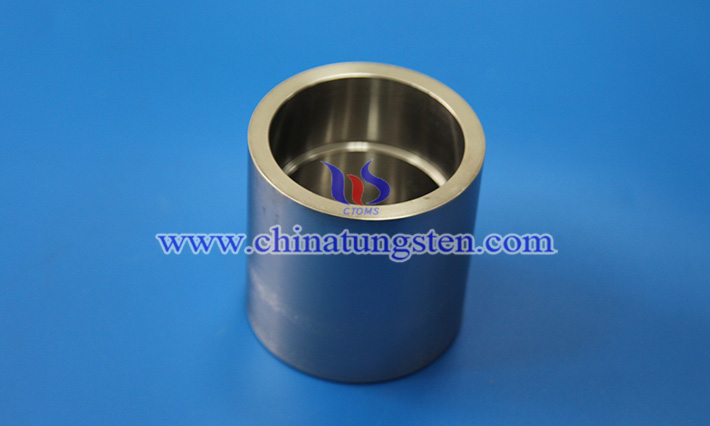

Tungsten is widely used in industrial scenarios such as high-temperature metallurgy, crystal growth, and vacuum smelting due to its ultra-high melting point, excellent high-temperature resistance and chemical stability. Especially in the preparation of molybdenum, titanium, rare earth and other active metal materials, tungsten crucible has become an ideal container material because it is not easy to react with the melt and can withstand extreme thermal stress.

At present, W crucibles are mainly prepared by powder metallurgy method, which can not only achieve the processing goals of high purity, densification and complex shapes, but also effectively improve the consistency and yield of products.

The basic process of powder metallurgy preparation of crucibles includes: raw material powder preparation, molding, sintering and subsequent processing and treatment.

The first is the preparation of raw material powder. Powder metallurgy has extremely high requirements for the particle size, morphology and purity of the powder, and the preparation of tungsten powder usually uses hydrogen to reduce tungsten compounds such as sodium tungstate and ammonium metatungstate (APT). In order to meet the structural stability of tungsten crucible in high-temperature environment, ultra-fine tungsten powder with uniform particle size distribution, high particle sphericity and very low impurity content is often selected. In recent years, some high-end manufacturers have even adopted plasma spheroidization technology or hydrogen plasma spheroidization technology to retreat tungsten powder to obtain a better dense structural basis.

This is followed by the molding stage, where cold isostatic pressing (CIP) and compression molding are commonly used. CIP technology can obtain a uniform and dense powder body by pressing tungsten powder in an all-round way in a high-pressure liquid environment, which provides a structural basis for subsequent high-temperature sintering. In contrast, molding is suitable for small batches of regularly shaped crucible products, but the density distribution is not as uniform as isostatic pressing. Some manufacturers are also exploring injection molding or 3D printing technologies to achieve more complex cavity structures or personalized customization.

High-temperature sintering is the most critical step in the powder metallurgy process, usually carried out in a high vacuum or hydrogen atmosphere of 1700~2000°C. The sintering process can be divided into two stages: pre-sintering and dense sintering, the former promotes the formation of a neck between the powder particles at a lower temperature, and preliminarily consolidates the green body; The latter promotes the diffusion of atoms at higher temperatures, densifying the green body. In order to improve the density and microstructure uniformity, some companies also use secondary sintering or hot isostatic pressing (HIP) technology to further eliminate micropores and residual stresses, so as to obtain high-strength and high-toughness crucibles.

The sintered crucible also needs to undergo precision machining and surface treatment, such as CNC turning, inner wall polishing, edge chamfering, etc., to ensure dimensional accuracy, surface finish and geometric stability. For special-purpose crucibles, molybdenum coatings or tungsten-tantalum alloy coatings can also be applied to further enhance corrosion resistance and high-temperature stability.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com