Failure Analysis of Tungsten Crucible in High-Temperature Experiments

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:01

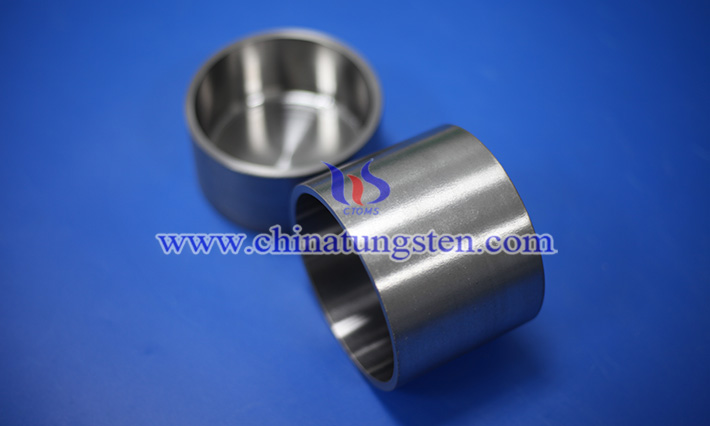

Due to its extremely high melting point, excellent high-temperature mechanical properties and good chemical stability, tungsten crucible is widely used in high-temperature experiments in aerospace, metallurgy, materials science and other fields, especially in crystal growth, metal smelting and rare element extraction, etc., which plays a key role. However, in the actual use process, tungsten crucibles are not "indestructible", and will still fail in different forms due to a variety of complex factors.

First, thermal fatigue cracking is one of the most common failure forms of tungsten crucibles. High-temperature experiments are often accompanied by dramatic temperature fluctuations, such as rapid heating and cooling cycles, which can lead to intense thermal stresses between the inner and outer walls of the crucible. Due to the high thermal conductivity and low coefficient of thermal expansion of tungsten, although this helps for rapid heat transfer, once the local temperature is uneven or the cooling rate is too fast, it is easy to form stress concentrations, which can induce fatigue cracks at microscopic defects. Over time, these cracks will gradually propagate, eventually leading to structural rupture.

Secondly, oxidation and volatile losses are also key factors in the failure of the W crucible. Although tungsten has good stability in vacuum or inert atmosphere, its surface is easily oxidized to WO₃ if there are trace amounts of oxygen, water vapor or strong reducing gas at high temperature in the experimental environment. Tungsten oxide is extremely volatile at high temperatures, which will lead to gradual loss, roughening, and even the formation of holes on the surface of the material, which may lead to thinning of the crucible wall thickness or even perforation. In addition, brittle substances formed during the oxidation process can be peeled off during temperature cycling, causing local cracking.

Thirdly, metal-to-metal reactions or corrosion are also concerns. In some experiments, the smelted materials (such as titanium, zirconium, rare earth metals, etc.) may react with tungsten at high temperatures to form brittle intermediate phases, resulting in a decrease in the interfacial bonding strength, and even the phenomenon of interfacial layer detachment and structural cracking. For high-purity experiments, this not only affects the service life of the crucible itself, but also causes contamination of the experimental sample, which affects the accuracy of the results.

Another failure factor that cannot be ignored is mechanical shock and loading and unloading damage. Although tungsten retains good strength at high temperatures, it shows a certain degree of brittleness at room temperature, especially after multiple thermal cycles, the crucible grain coarsening, internal residual stress accumulation, once hit by external force or clamping too tightly, may cause cracking or edge breakage.

In order to slow down the occurrence of the above-mentioned failure forms, the following measures are usually recommended: first, optimize the heating and cooling curves to avoid thermal shock caused by rapid temperature changes; Second, maintain a vacuum or high-purity inert atmosphere during use to prevent oxidation; Third, if necessary, a protective coating, such as molybdenum or nitride, can be applied to the inner wall of the crucible to isolate reactive substances; Fourth, flexible support should be used in the process of handling and installation to avoid mechanical stress concentration.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com