Chemical Stability Studies of Tungsten Crucibles

- Details

- Category: Tungsten Information

- Published on Monday, 30 June 2025 11:07

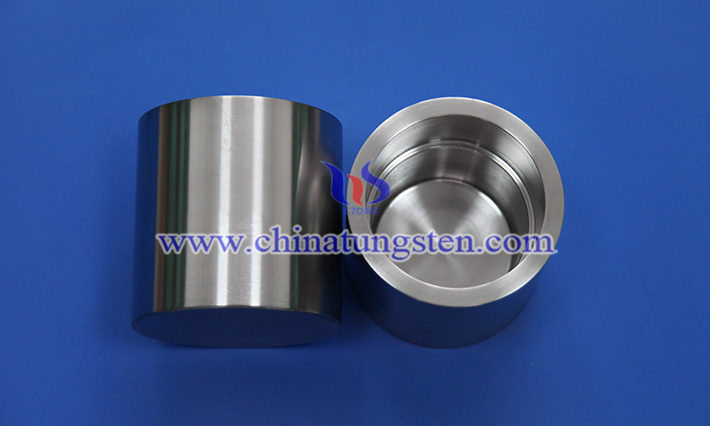

Tungsten material is widely used in high-temperature thermal field, vacuum smelting, crystal growth and other cutting-edge scientific and technological fields. In these applications, tungsten crucibles have become important vessels for carrying molten metals or chemical reactants due to their advantages of high temperature resistance, high thermal conductivity, and non-deformation.

However, while tungsten is excellent in terms of physical properties, its chemical stability is affected by a variety of factors, such as temperature, atmosphere, and contact substances. Therefore, it is of great significance to systematically study the chemical stability of tungsten crucible to improve its service life and ensure the safety and reliability of the experimental and production environment.

First, the chemical stability of tungsten exhibits excellent stability in an inert atmosphere or high vacuum. Under argon, helium or vacuum, tungsten remains chemically inert even when the temperature rises above 2000°C, and the surface is virtually non-reactive. This makes tungsten crucibles ideal for the preparation of high-purity materials and the growth of single crystals, such as smelting processes for sapphire crystals or high-purity titanium. However, once the atmosphere contains trace amounts of oxygen, water vapor or halogens, the chemical stability of tungsten decreases significantly.

In an oxidizing environment, tungsten is highly susceptible to oxidation, especially at temperatures above 400°C, resulting in tungsten trioxide (WO₃). The oxide has obvious volatility, which will gradually thicken the surface of the W crucible and even damage the physical structure, which will affect its strength and sealing performance. In addition, when exposed to oxygenated melts (e.g., silicon, alumina, borate, etc.) at high temperatures, tungsten may engage in complex chemical reactions, forming oxides, intermetallic compounds, or silicides that are difficult to control, resulting in crucible failure.

In addition, tungsten reacts in certain highly reducing or halogen atmospheres. For example, although tungsten is generally relatively stable in hydrogen, if the temperature is too high (such as more than 1600°C) or the hydrogen contains trace amounts of halogen impurities, such as fluorine or chlorine, it may induce the fluorination or chlorination reaction of tungsten to form volatile WF₆, WCl₆ and other products. These reactions not only accelerate tungsten loss, but can also cause corrosion to the vacuum system, posing a safety hazard to the equipment.

In order to improve the chemical stability of tungsten crucibles, the researchers proposed a variety of improvement strategies. Common methods include coating its surface with an inert metal or compound, such as molybdenum, hafnium, boron nitride, etc., to form an insulating protective layer. These coatings both retard oxidation reactions and prevent direct contact between tungsten and melt at high temperatures. In addition, the use of high-purity atmosphere protection, optimized temperature control schemes, and limited reaction time have also been shown to help improve the chemical stability of the W crucible under real-world operating conditions.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com