Heating Glass Technology: Thermal Conduction Mechanism of Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Friday, 27 June 2025 17:00

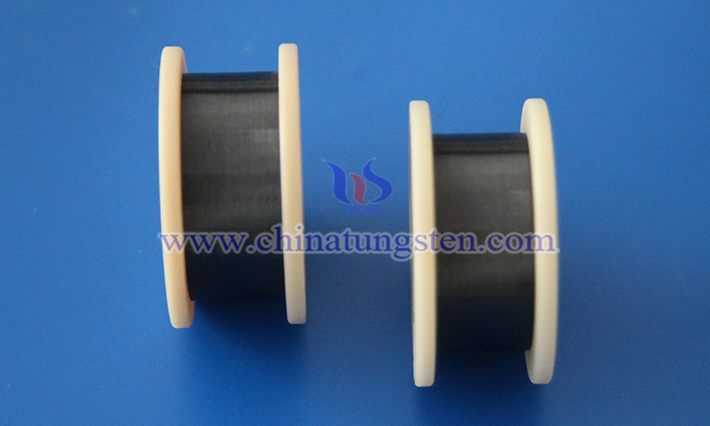

In heating glass technology, tungsten wire is an efficient heating element, and its thermal conduction mechanism mainly involves heat generation, transfer and interaction with glass substrate.

Tungsten wire is widely used in heating glass technology due to its high melting point (about 3422℃), low thermal expansion coefficient and excellent conductivity. When powered on, tungsten wire generates Joule heat due to the resistance effect, and heat is mainly transferred in three ways: conduction, convection and radiation. In the glass heating scene, conduction and radiation are the main mechanisms. The high temperature of tungsten wire intensifies its electronic vibration and generates a large amount of heat energy, which is transferred to the surrounding environment through intermolecular collisions.

The core of the thermal conduction mechanism lies in the energy transfer inside the tungsten wire and at the interface with the glass. The thermal conduction inside the tungsten wire follows Fourier's law: the heat flux density is proportional to the temperature gradient, and the high thermal conductivity of tungsten (about 173 W/m·K) ensures rapid heat diffusion. The tungsten wire surface transfers heat to the glass through radiation. The radiation follows the Stefan-Boltzmann law, and the thermal power is proportional to the fourth power of the temperature. Since the tungsten wire emits strong infrared radiation at high temperatures (>2000℃), the glass absorbs these radiations and the molecular vibrations intensify, causing the temperature to rise rapidly. In addition, there may be a small contact between the tungsten wire and the glass, and the heat is transferred to the glass surface by direct conduction.

In heating glass applications, the thermal conductivity of the tungsten wire is controlled by the environment. A vacuum or inert gas (such as argon) environment can reduce oxidation and convection losses and enhance radiation efficiency. The geometry of the tungsten wire (such as spiral or straight) also affects the uniformity of heat distribution. Optimizing the design can improve the uniformity and efficiency of glass heating.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com