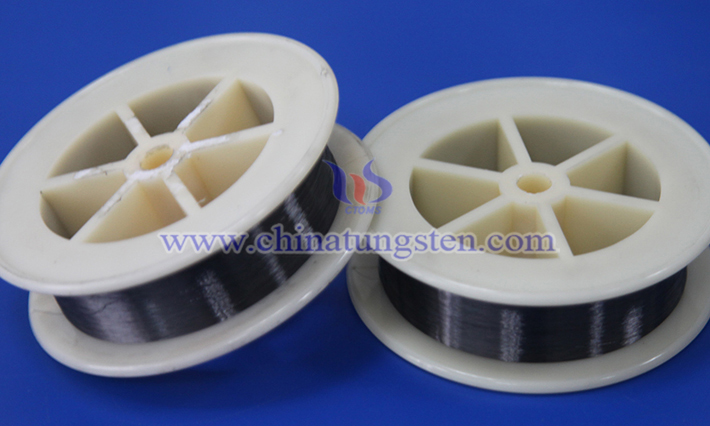

Cut-Resistant Tungsten Wire for Metal Cutting

- Details

- Category: Tungsten Information

- Published on Monday, 07 April 2025 18:39

Cut-resistant tungsten wire is a key material in the metal cutting domain. It is widely applied due to its extremely high melting point (approximately 3422°C), exceptional tensile strength, and high-temperature stability, particularly excelling in processing tasks that demand precision and durability.

I. Key Advantages of Cut-Resistant Tungsten Wire

1. High Melting Point: Tungsten has one of the highest melting points among known elements. Even under prolonged high-temperature working conditions, cut-resistant tungsten wire maintains its structural integrity without deforming or breaking easily.

2. High Hardness and Wear Resistance: With its remarkable tensile strength and wear resistance, cut-resistant tungsten wire can withstand the heat and friction generated during metal cutting, extending its service life.

3. Fine-Diameter Processing Capability: The wire can be drawn into very thin diameters (typically between 0.01mm and 0.3mm), making it suitable for cutting complex shapes or small metal parts.

4. Conductivity: In wire electrical discharge machining (Wire EDM), cut-resistant tungsten wire serves as an electrode, cutting metal through the principle of electrical discharge erosion. It requires good conductivity, a requirement that tungsten wire fully meets.

II. Main Application Scenarios of Cut-Resistant Tungsten Wire

1. Wire EDM Cutting: As a conductive wire, cut-resistant tungsten wire is used in metal cutting via electrical discharge erosion, commonly applied to process hard metals (such as die steel) or materials with good conductivity.

2. Precision Parts Processing: Thanks to its ability to be drawn into extremely fine diameters, it is ideal for cutting small or intricately shaped metal components, such as watch parts or medical device elements.

3. Scientific Experiments: In experiments requiring high-precision cutting, cut-resistant tungsten wire serves as a metal cutting tool, particularly for handling small samples or special materials.

III. Precautions for Using Cut-Resistant Tungsten Wire

It must be used in a suitable operating environment to prevent oxidation (tungsten reacts with oxygen at high temperatures).

Cutting parameters (such as current and speed) should be adjusted based on the specific metal material to optimize efficiency and precision.

Regularly inspect the wear condition of the tungsten wire and replace it promptly to ensure cutting quality.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com