How to Handle the Surface Treatment of Iodine Tungsten Lamp?

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 August 2023 22:35

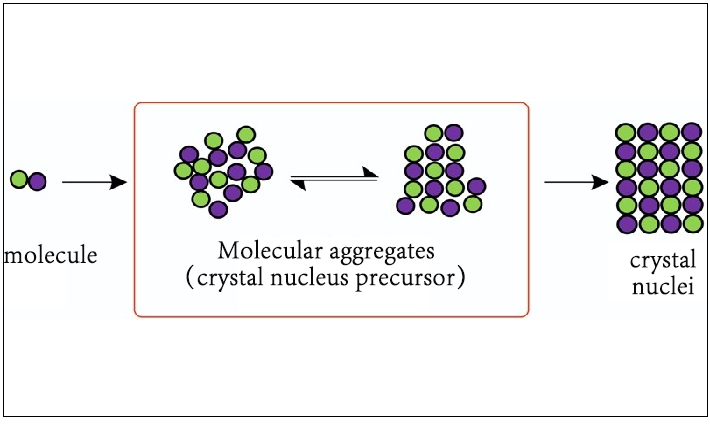

An iodine tungsten lamp is a kind of high-efficiency lighting fixture, which is generally composed of tungsten wire and quartz glass shell. Because of its small size and high internal temperature, the glass shell will undergo a cycle of "melting-cooling-solid reheating" after use. If there is an impurity attached to the bulb shell and the surface treatment is not carried out in time, the atomic arrangement of quartz glass will change at high temperatures, causing the surface to crystallize and lose its transparency. This phenomenon is called devitrification.

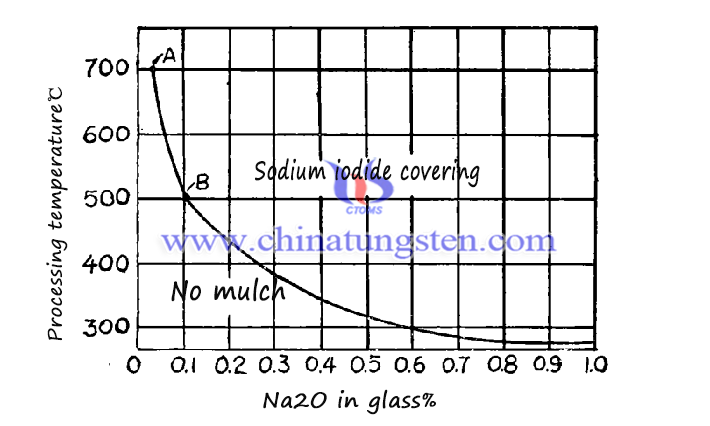

To extend the lifespan of an iodine tungsten lamp, surface treatment is usually carried out on the shell. The common surface adhesions are alkali metals such as sodium and potassium. The solution is the protective layer on the outer shell, which is a good way to prevent the temperature from rising and isolate the alkali impurity from diffusing into the inner crystal core.

Based on the characteristics of iodine tungsten lamps, researchers listed aluminum oxide, boron oxide, and phosphorus pentoxide as alternatives and conducted experiments. Finally, boron oxide was selected as the covering material for surface treatment. The difference between the thermal coefficient of boron oxide and the covering coefficient of quartz glass with a low coefficient is small, even if the internal temperature rises, it is not easy to produce cracks. Moreover, boron oxide will diffuse into silicon dioxide at high temperatures above 1100℃ to form an extremely thin protective layer of 1-2 microns. The protective layer is transparent and has no obvious boundary with quartz glass. The transmittance of visible light and the difference between quartz glass are small, which will not affect the illumination function of iodine tungsten lamps. Therefore, the quartz glass with this protective layer will not cause splitting and decrease in heat resistance even if it is repeatedly heated to 900-1200℃. This kind of glass has good characteristics when applied to iodine tungsten lamp light sources such as projection photography.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com