Synthesis of Micro-Spherical Tungsten-Molybdenum Alloy

- Details

- Category: Tungsten Information

- Published on Thursday, 28 October 2021 22:54

In recent years, tungsten-molybdenum (W-Mo) alloys have attracted great interest as high-temperature materials for various applications. W-Mo alloy has excellent performance in preventing corrosion of molten zinc, and can be used at higher temperatures than molybdenum or molybdenum alloys. It is used for zinc liquid temperature measuring tube, zinc liquid pump rotor, and some corrosion-resistant parts of zinc smelting furnace. Because of its high melting point, ablation resistance, and flame retardancy to solid particles. tungsten-molybdenum alloy can also be used for the air rudder and protective cover of solid rocket motors. In addition, it is also used in the production of stirring tools in the glass industry, the manufacture of thin film transistors, the sputtering target for flat screen coating and the treatment of molten metal.

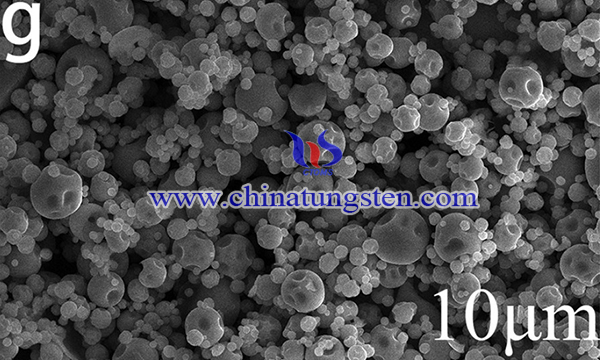

Micro-spherical tungsten‑molybdenum alloy (W-Mo) is prepared by spray drying combined with two-step microwave assistant calcination from commercial (NH4)10W12O41 and (NH4)6Mo7O24. The preparation process is as following steps:

First, a commercial spray drying machine (B290, Buchi, Switzerland) was used to prepare the spherical (NH4)10W12O41-(NH4)6Mo7O24 particles. A two-fluid nozzle was used as the atomizer. The temperatures at the inlet and outlet of the spray dryer were 140 °C and 85 °C, respectively. The atomization pressure was 0.6 MPa, and the feed rate of the precursor was 4 ml/min. The spraying dried (NH4)10W12O41-(NH4)6Mo7O24 particles need further heat treatment to be the W-Mo alloys powder. Firstly, the spraying dried powder was calcined in N2/H2 (Vol 5:1) at 650 °C for 2 h followed by cooling under N2/H2 in a self-made microwave tube furnace. Then, the 1st-calcined powder was continued ignited in N2/H2 (Vol 5:1) at 850 °C for 2 h followed by cooling under N2/H2 in the self-made microwave tube furnace. Well-dispersed micro-spherical W-Mo alloys particles were synthesized. As-synthesized W-60 wt% Mo alloy powder was uni-axially compacted to form pellets (10 mm diameter, about 4 mm height) under a pressure of 120 MPa without adding any external lubricant. The compact was sintered under H2 atmosphere at 1550 °C (heating rate 20 °C/min) for 2 h. The density of the sintered specimen was measured by Archimedes method.

In conclusion, the well-dispersed Micro-spherical tungsten‑molybdenum alloy were synthesized by spray drying combined with two-step microwave assisted calcination process from commercial (NH4)10W12O41 and (NH4)6Mo7O24. The size distribution of as-synthesized W-Mo alloys particles (two-step calcination) was between 1 and 8 μm, and the average size was about 3 μm. W60Mo alloy compact was achieved by sintering as-synthesized W60Mo alloy powder. The relative density and Vickers hardness were 98.8% and 421 ± 10 Hv, respectively.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com