Printing of WO3/ITO Electrochromic Films

- Details

- Category: Tungsten Information

- Published on Sunday, 17 October 2021 23:49

Electrochromic smart devices with controllable optical properties are the most promising alternatives to traditional doors and windows. The existing technology preparation and commercialization of large-scale electrochromic films are mainly based on vapor deposition, but large-scale applications are limited by high prices (due to the complex preparation process).

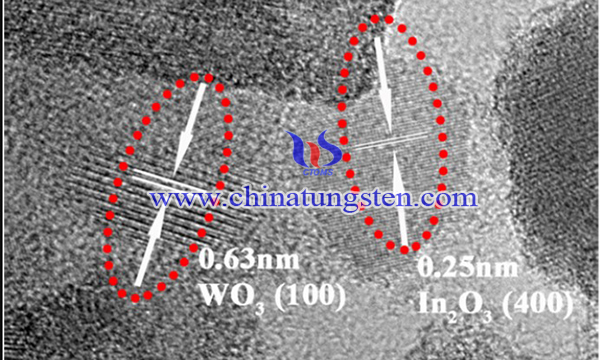

Scientist have combined tungsten trioxide (WO3) with indium tin oxide (ITO) to prepare WO3/ITO electrochromic films with enhanced electrochromic properties by a wet chemical wire-bar process. The method is suitable for large-area low-cost preparation. The preparation process of WO3/ITO electrochromic films is as below:

WO3 nanoparticles were synthesized using the reported hydrothermal process. Sodium tungstate dihydrate (Na2WO4·2H2O, 99%) and HCl aqueous solution were used as the precursor. In a typical experiment, 0.815 g of Na2WO4·2H2O was dissolved in 10 mL of deionized water. Then Na2WO4 solution was acidified to a pH value of 2.0 using HCl (3 mol/L) solution at room temperature. Then, the solution transferred into a Teflon-lined 45 mL capacity autoclave where hydrothermal reaction was carried out at 180 °C for 24 h. After the reaction, the final products were washed sequentially with deionized water and ethanol to remove the sulfate ions and other remnants by centrifugation. Finally, a pale yellow product, WO3 nanopowder was obtained.

Polyethylene glycol (0.15 g) and BYK2013 (0.1 g) were added into an ethanol solution (4.75 g), and then the WO3 nanopowders and ITO nanoparticles were weighted according to the composition of x (x = ITO/WO3, 0%, 10%, 20%, 30% and 40% in weight), respectively, and the total amount of ITO and WO3 is fixed (1.25 g). After that the mixture was milled with ZrO2 beads for 10 h at 3000 rpm.

The ITO substrates were cleaned by isopropyl alcohol and treated with Ar plasma, and then NPs dispersions with different ITO content were coated on processed ITO glass (ITO film/glass) by wire-bar method, respectively. Firstly, before the process of coating, we fixed the treated ITO glass on the coating machine, then set the machine speed to 10 mm/s and used 1 µm wire rod. At last, all the samples were annealed at 300 °C for 1 h to establish good contact between composite films and substrates. The prepared transparent EC films with the 0%, 10%, 20%, 30% and 40% ITO are denoted according to the following nomenclature I0, I10, I20, I30 and I40.

In summary, WO3/ITO electrochromic films for large-area low-cost preparation were successfully developed. The high-conductivity ITO nanoparticle network and the ITO coating on the glass can be used as an extended 3-dimensional electrode to form a micro-electric field and serve as a way for electrons to diffuse into WO3 nanorods. The results show that the surface resistance of the WO3/ITO nanocomposite film is reduced to 32% compare to pure WO3. The optimized WO3/ITO film exhibits higher light modulation (ΔT = 81.7% vs 62.5% at 630nm) and faster switching speed (tb = 6s vs 22s) than the original WO3 with ITO content between 20% and 30%.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com