WO3 Modified TiO2 Nanotube Array for Rhodamine B Degradation

- Details

- Category: Tungsten Information

- Published on Friday, 24 September 2021 00:49

The main source for water and soil pollutions is hazardous colorants in waste water discharged from textile industries. Rhodamine B (RhB) is the most used dye in the textile industries hence it is widely considered as a typical water pollutant. Among the several methods available today, the removal of Rhodamine B dye from the textile waste water via photocatalytic degradation has received much attention from researchers because it can convert the Rhodamine B dye into water, carbon di-oxide and mineral acids without creating secondary pollutants.

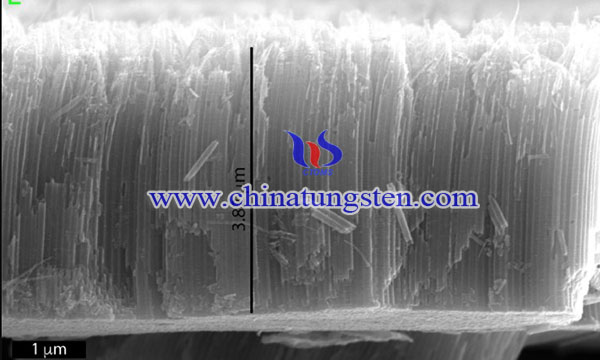

Recently, scientists have introduced a high-efficiency photocatalyst based on the titanium oxide (TiO2) nanotube array decorated with tungsten trioxide (WO3) is prepared by electrochemical deposition. An efficient photocatalyst as WO3 modified TiO2 nanotube array for rhodamine B degradation has been synthesized by electrochemically depositing WO3 on a titanium nanotube (TNT) array. The synthesis of is as follows:

First, electrochemical anodization was applied to 1.0 × 3.0 cm titanium (Ti) foil. The foil was cleaned by ultrasonic stirring in acetone, isopropanol, and deionized water for 30 minutes, respectively. Then, the foil is placed in the electrochemical cell in the anode compartment, while the platinum mesh is the cathode. A cell solution containing ethylene glycol, 0.4% (w/w) NH4F and 5% (w/w) deionized water was added, and a direct current potential (40 V) was applied for 4 h under magnetic stirring at room temperature. Take the array out of the battery, immerse it in methanol for 1 minute to remove any residue and rinse with water. Finally, it is annealed in ambient air at 450°C for 1 hour, allowing the phase change from amorphous to anatase.

The electrode was modified by immersing an array with a surface area of 2.0 cm2 in a cell containing 0.03 M tungstate solution in a mixture of 0.01 M H2SO4 and 0.1 M H2O2. The platinum wire is used as the counter electrode. Then, scan the potential for two cycles at a rate of 50 mV s-1 between -0.6-1.0 vs Ag/AgCl.

Then, WO3 was decorated on TNT electrodes by cycling the potential from -0.6 – 1.0 V vs Ag/AgCl several times. The peak near -0.3 V can be attributed to the reduction of peroxotungstic acid on the TNT surface, and the peak shifts in the positive direction as the number of cycles increases. The potential change caused by increasing the number of cycles clearly shows that a WO3 layer is formed on the TNT electrode.

In short, an efficient photocatalyst as WO3 modified TiO2 nanotube array for rhodamine B degradation has been synthesized by electrochemically depositing WO3 on a titanium nanotube (TNT) array. XRD and XPS results show that WO3 substances exist in an amorphous and/or highly dispersed state on the surface of TiO2 nanotubes. This electrode has the best performance for rhodamine B compared with the bare TNT electrode. The result showed that effective dye removal can be achieved within 10 minutes.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com