MoSe2/WO3 Thin Films for Fabrication of Excellent Electrochromic Devices

- Details

- Category: Tungsten Information

- Published on Thursday, 09 September 2021 13:03

In recent years, electrochromic devices (ECD) have attracted attention due to their unique light transmission characteristics. It provides some potential applications, such as energy savers, colored glass, and gas sensors. In the ECD family, tungsten trioxide (WO3) films have been extensively studied due to their high color transfer efficiency with hydrogen ion reaction. Therefore, WO3 film is suitable as a good hydrogen sensor element.

In the current research, molybdenum disulfide (MoSe2) is used as a conductive carrier for the preparation of MoSe2/WO3 (MSW) films to enhance the conductive properties of WO3, which may be beneficial to the electron transport process. A new type of MSW film was developed on indium tin oxide (ITO) glass substrates and flexible substrates (ITO/PET). Therefore, MoSe2/WO3 film has been manufactured as an excellent electrochromic device (ECD) for smart window applications. The incorporation of MoSe2 not only improves the EC performance, but also enhances the stability of the developed ECD for 10,000 cycles. The synthesis of WO3-based electrochromic devices is as follows:

In a separate beaker, Na2MoO4·2H2O (1.1 mmol) was dissolved in 35 mL of distilled water, and Se powder (2.2 mmol) was dissolved in 7 mL of hydrazine hydrate. Subsequently, the hydrazine hydrate-Se solution was gradually added to the Na2MoO4·2H2O solution. Finally, the reaction mixture was transferred to a stainless-steel autoclave lined with polytetrafluoroethylene (capacity 100 mL), heated in an oven at 200 °C for 14 h, and then cooled naturally. The precipitate was collected by centrifugation at 8000 rpm for 5 minutes. Then wash several times with deionized (DI) water and ethanol to remove any impurities or residual materials. The final product was dried overnight at 70°C in a vacuum oven.

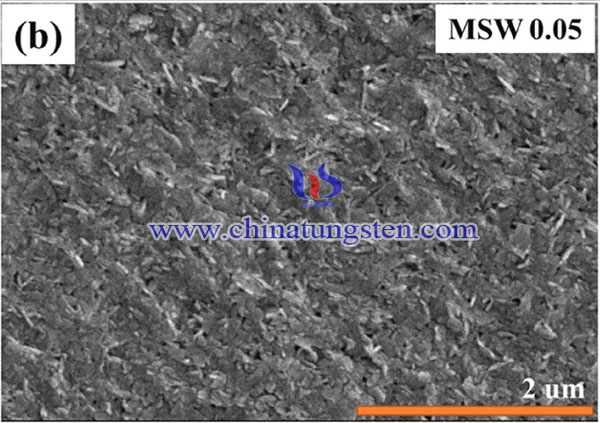

Then, tungsten powder (6.8g) and H2O2 (31wt% in H2O; 93.2g) were mixed and stirred overnight. The solution was heated at 100°C to evaporate the solvent, and then a light yellow WO3 powder was obtained. Subsequently, MoSe2/WO3 samples (MSW) with different weight percentages (0.05, 0.2 and 0.5) of MoSe2 were prepared. Disperse WO3 (30 wt%) in a mixture of isopropanol and deionized water (ratio = 50:50) and sonicate for 6 hours, then add MoSe2 (0.05 wt%) to the WO3 solution and sonicate for another 6 hours . The samples with different weight percentages of MoSe2 (0.2 weight percentage and 0.5 weight percentage) were also prepared in a similar manner. The resulting solution was then used to make MSW thin films. The prepared samples containing 0.05 wt%, 0.2 wt%, and 0.5 wt% MoSe2 are labeled MSW 0.05, MSW 0.2, and MSW 0.5, respectively.

Use an ultrasonic generator to disperse WO3 or MSW samples (30 wt%) in a water:isopropanol (1:1) mixture for 6 hours. Use a spin coating process (spin coating speed = 5000 rpm; time = 30 s) to clean the ITO glass substrate and prepare a thin film of WO3 or MSW samples. Then the WO3 and MSW films fabricated on ITO were annealed in a vacuum oven at 60°C for 8 hours. MSW 0.05 films on ITO substrates were also prepared at different annealing temperatures (100°C and 150°C) to study the effect of annealing temperature.

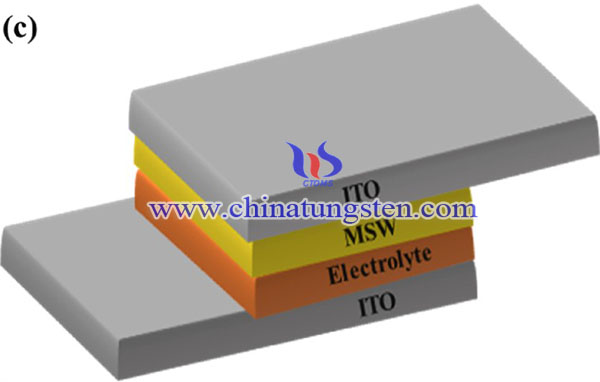

To make ECD, 500 μL of electrolyte (10 wt%) solution (containing 0.05 M ferrocene and 0.5 M lithium perchlorate in propylene carbonate) was drop-cast on MSW-coated ITO glass. Other ITO glass is placed on the MSW-coated ITO glass substrate. For sealing, surlyn tape (2 × 2 cm2) was added between the two ITO glass substrates and heated at 100°C for 30 minutes. Flexible ECD based on ITO/PET is also manufactured under similar conditions.

In conclusion, MoSe2/WO3 film has been manufactured as an excellent electrochromic device (ECD) for smart window applications. The ECD synthesized with MSW 0.05 showed a higher coloring efficiency (62 cm2 C-1), and the applied potential range was 0 to -1.5 V. Subsequently, ECD based on indium tin oxide (ITO) and MSW 0.05 showed excellent electrochromic performance and stability for 10,000 cycles.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com