Ammonium Paratungstate for Preparing Superfine W–Cu Powders

- Details

- Category: Tungsten Information

- Published on Thursday, 09 September 2021 22:02

Tungsten-copper (W-Cu) composite materials have comprehensive properties such as good thermal conductivity, electrical conductivity, low thermal expansion, non-magnetic, good performance under vacuum, and arc corrosion resistance, and are widely used in civil industry and aerospace fields. Therefore, they are often used as electrical contacts, especially in high voltage applications.

Thus, a precursor powder containing oxides and salts of tungsten and copper was synthesized from ammonium paratungstate and copper nitrate by the GNP method, Ammonium paratungstate has been utilized as the tungsten source for preparing superfine W–Cu powders, the powders have particle size of about 200 nm and with good sinterability.The preparation process of W-Cu powders is as below:

Copper nitrate trihydrate [Cu(NO3)2·3H2O], ammonium paratungstate [(NH4)6H2W12O40·xH2O] and glycine [C2H5NO2], one end is carboxyl group, the other end is amino group, used as complexing agent and burning agent. The stoichiometric chemical is dissolved in distilled water to obtain a mixed solution. Then glycine is added to the solution to form a transparent and uniform solution, and then heated, the viscosity of the solution gradually increases. As the temperature rises, self-sustained combustion eventually occurs in the viscous gel and dark precursor powder is obtained. After calcination at 400°C for 2 hours to remove organic residues to form a stable crystal structure, the precursor was then reduced at 650°C, 700°C, and 750°C in a hydrogen atmosphere for 90 minutes to obtain W – 20Cu powder. For the sintering study, the W-20Cu composite powder obtained by reducing the precursor in H2 for 90 minutes at 700°C was pressed at 200 MPa into cylindrical particles with a diameter of 18 mm and a thickness of 2 mm. The green density of the compact is approximately 55%. Then the pressed W-20Cu powder compact was sintered in an H2 atmosphere at 1050-1200°C for 2 hours. The heating rate and hydrogen flow rate are 5 °C min-1 and 100 mL/min, respectively.

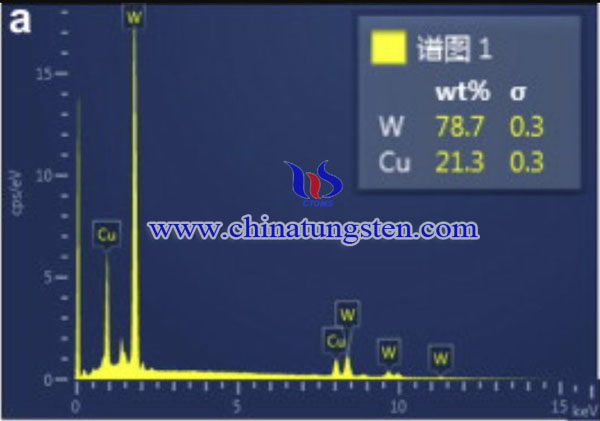

In short, ammonium paratungstate has been used as a tungsten source for the preparation of ultrafine W-Cu powders with a particle size of about 200 nm and good sinterability. A glycine-nitrate process (GNP) reduction method was proposed to prepare W-20 wt.% Cu powder (W-20Cu). The particle size of the obtained W-20Cu powder is about 200 nm, and the powder shows good sinterability. The powder compact was sintered in an H2 atmosphere at 1200°C for 2 hours to obtain a relative density of more than 98.5%. The sintered W-20Cu compact also obtained a uniform microstructure, good physical and mechanical properties. Generally, the conductivity and Vickers hardness of W-20Cu samples sintered at 1200 °C for 2 hours are 40.1% IACS and 278 HV, respectively.

- Tungsten Copper Manufacturer & Supplier, Chinatungsten Online: tungsten-copper.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com