Wet Chemical Synthesis of Tungsten/Titanium Carbide Composite by Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Monday, 23 August 2021 01:00

In the development of tungsten-based Plasma Facing Materials/Components (PFMs/PFCs), materials scientists have explored many different, innovative preparation and processing routes to meet the requirement of International Thermonuclear Experimental Reactor (ITER). Tungsten (W) is one of the best candidates for plasma-facing materials in the fusion reactors, owing to its many unique properties. However, some inherent defects such as the embrittlement, high DBTT of tungsten material restrict its application on PFMs and PFCs.

Nanostructured W materials were proposed to improve the performance of W matrix materials for use in fusion reactors. Meanwhile, nanostructured W materials can be efficiently fabricated by doping W with nanoparticles, such titanium carbide (TiC), lanthanum oxide (La2O3), and yttrium oxide (Y2O3).

In order to enhance the performance of tungsten materials, Tic has doped on tungsten to fabricate a new PFM composite material. tungsten/titanium carbide composite (W-TiC) has been successfully prepared by ammonium paratungstate in a wet chemical route. The synthesis process of W-TiC composite is as below:

The powder was prepared from the nanosized second-phase TiC particles (commercial powder, particle size about 50 nm, purity 99.9%) and ammonium paratungstate (NH4)10H2W12O42 · XH2O (APT). The ratio of the dopant TiC is 1.0 wt.%, which was calculated by stoichiometry. Oxalic acid (C2H2O4 · 2H2O) acted as the precipitating agent to prepare the precursor. During the process, called as evaporating precipitation, the precursor was precipitated from the mixture solution, which resulted from a reaction that with the concentration of oxalic acid increased which was owing to the solution evaporation at 165 °C. After grinding, the precursor was placed in a tubular furnace with a highly pure hydrogen atmosphere (purity = 99.999%) for reduction. Reduction was performed by increasing the temperature to 200 °C for 30 min to exclude the low sublimation point of the residual inorganic material. Then, a two-step reduction process was carried out by heating to 500 °C for 60 min and then to 800 °C for 60 min, and finally the material was cooled.

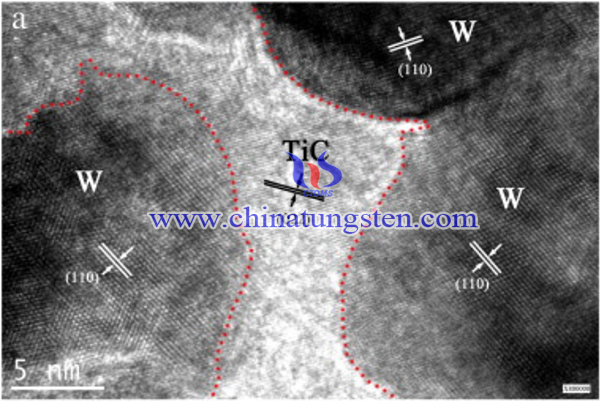

In summary, tungsten/titanium carbide composite has been successfully prepared by ammonium paratungstate in a wet chemical route. The as-synthesized powders possessed a uniform diameter of about 30 nm to 100 nm and contained only nanosized W and TiC particles. The result revealed that nanosized TiC particles were initially coated with a W precursor, and then with nanosized W particles through in situ reduction. In addition, HRTEM images or diffraction ring spectrum verified that the central particle was the TiC phase, and that the surrounding particles were the W phase.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com