Tungsten Doped CeO2/TiO2 with Ammonium Paratungstate for SCR of NOx

- Details

- Category: Tungsten Information

- Published on Thursday, 08 July 2021 22:48

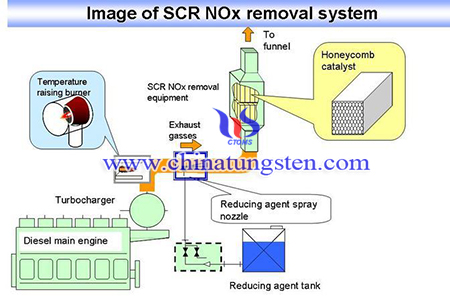

Nitrogen oxides (NOx) are emitted from various industrial processes and transportation activities, especially coal–fired power plants. The SCR catalysts that are most used are those in which WO3 is added to VOx/TiO2 (anatase). These vanadium-based catalysts exhibit an excellent efficiency in a temperature range from 300 to 400 °C . However, these vanadium-based catalysts also suffer from several drawbacks, including the harmful effects of vanadium on the environment, the high likelihood of SO2 oxidizing to o SO3, a narrow operation temperature window (300–400 °C), and the formation of N2O at high temperatures.

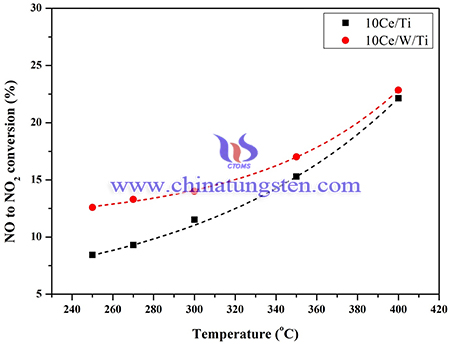

In particular, ceria is a potential substitute for vanadium due to its oxygen storage capacity and high redox ability when shifting between Ce4+ and Ce3+. Production of tungsten doped CeO2/TiO2 has been achieved with ammonium paratungstate for SCR of NOx, The Ce/Ti with 10 wt.% ceria (10Ce/Ti) exhibited excellent activity.

The preparation method of the SCR catalyst is as following steps: Cerium (III) nitrate [10 wt.% Ce; Ce(NO3)3·6H2O by using ceria (5, 10, 20, and 50 wt.% Ce) and anatase-type TiO2 powder (DT51) had been used as precursors. A calculated amount of TiO2 was gradually added to the ceria solution while stirring. The mixture was agitated in a slurry state for more than 1 h; then the moisture was removed at 70 °C using a rotary vacuum evaporator (Eyela Co., N–N series); and the mixture was dried overnight at 110 °C. Finally, the mixture was calcined in air for 5 h at 500 °C.

The 10Cesingle bondW/Ti catalyst was prepared according to the following process. Cerium nitrate (10 wt.% Ce) and ammonium paratungstate (10 wt.% WO3) were mixed in distilled H2O. The calculated amount of the TiO2 support was impregnated in this solution by stirring for 1 h, and then the moisture was removed at 70 °C using a rotary vacuum evaporator. The mixture was then dried overnight at 110 °C, and was subsequently calcined in air for 5 h at 500 °C. W/10Ce/Ti was prepared through impregnation of 10Ce/Ti and ammonium paratungstate using the method described above.

To sum up, tungsten doped CeO2/TiO2 has been produced with ammonium paratungstate for SCR of NOx, The Ce/Ti with 10 wt.% ceria (10Ce/Ti) exhibited excellent activity. Thus, various metals were added to the 10Ce/Ti. The tungsten-doped 10Ce/Ti catalyst exhibited the highest activity. The highest Ce3+ ratio was observed in 10Ce/W/Ti at 0.3027, and the catalyst efficiency had a positive correlation with higher Ce3+ ratios. The SCR activity was found to increase as the Ce3+ ratio increased when tungsten was added to 10Ce/W/Ti. Thus, the addition of tungsten to Ce/Ti resulted in excellent NOx conversion and SO2 resistance.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com