Synthesis of Tungsten Oxide Nanopowders by APT for applications in gas sensors

- Details

- Category: Tungsten Information

- Published on Thursday, 08 July 2021 10:05

WO3 is a popular and least bothered an n-type semiconductor with promising electrochemical properties, a high surface area, a small pore-size distribution, with several exciting chemical and physical properties, which have made it a appropriate material for various applications such as catalysts, gas sensors, and energy storage applications. However, the conventional synthesis methods have the drawbacks of high cost, time consuming, and high environmental pollution.

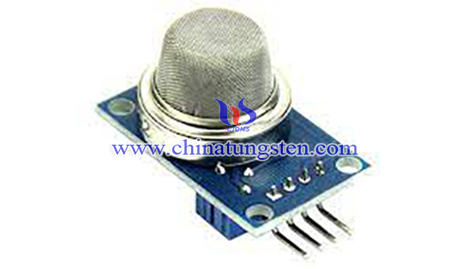

Hydrothermal synthesis has received great consideration because of its simplicity, cost-effectiveness, soft chemical approach, low-temperature processing, and uniqueness in producing controlled shapes/sizes of various nanostructures. The WO3 nanopowder gas sensors approve higher selectivity towards ammonia, than other VOCs such as ethanol, methanol, acetone, and toluene. The sensor for ammonia gas endows an ultra-fast response/recovery time. The schematic of gas sensing mechanism using a band structure change is closely analogous to experimental findings. The WO3 NBs gas sensor has also demonstrated remarkable sensing response for humidity.

The hydrothermal synthesis of tungsten oxide nanobricks using ammonium paratungstate (APT) as the raw material has followed the procedures: Analytical grade ammonium paratungstate (NH4)10[H2W12O42]·4H2O, 99%), hydrochloric acid (HCl, 37%), and hydrogen peroxide (H2O2, 30% w/w in water)were used as received. In a facile synthesis process, 1 g of ammonium paratungstate was mixed in 95 ml distilled water(Milli-Q water; 18.2 MΩ cm) and concentrated HCl(∼3 ml) and then stirred for a while. The stirring time was depending on the amount of HCl added. After the addition of nearly 2 ml of H2O2, the ammonium paratungstate solution initially turned to a transparent light yellow and then dark yellow by forming gelatinous precipitate, which was evidenced after continuously 1 h stirring to form transparent solution.

A transparent solution was poured in a stainless-steel Teflon-lined autoclave. The hydrothermal synthesis reaction was conducted at a constant temperature of 160 °C for∼14 h (heating rate 5 °C min−1). The whitish powder was taken off, rinsed with distilled water and calcinated at 500 °C for 1 h to increase the crystallinity of the as-obtained WO3 NBs. The solid-state film was fabricated by taking 1 g of polyvinyl alcohol (PVA) in 10 ml of distilled water as a binder, which was kept at 90 °C while constant stirring until the solution became viscous. Then, a few drops of viscous PVA solution was mixed with the WO3 NBs in a pestle and mortar. This mixture was coated onto a soda-lime glass substrate and dried at 300 °C to vaporize the excess water and binder. The obtained film was used as a room-temperature gas and humidity sensor.

In conclusion, tungsten oxide nanopowders has been successfully prepared using APT as raw material targeting the applications of gas sensors, it has a high sensitivity and selectivity when used for liquid ammonia and humidity sensor activities at room temperature. The gas sensing performance of WO3 NBs sensor was measured for the detection of ammonia and humidity at room-temperature (27℃). The highest response of 75% and ultrafast 8/5 s response/recovery time were obtained at 100 ppm concentration of ammonia. In addition, an excellent humidity response (32%) was displayed by the WO3 NBs sensor at a relative humidity (RH) of 20%.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com