Production of Tungsten Nanosized Powders with APT by RF Induction Thermal Plasma

- Details

- Category: Tungsten Information

- Published on Friday, 09 July 2021 04:18

In recent years, ultrafine tungsten powders have gained attention owing to their excellent characteristics. They have been added to hard metals and alloys with superior hardness and wear resistance. Ammonium paratungstate (APT), as important tungsten compound in tungsten industry, is usually utilized to produce metallic tungsten. However, the reduction process from APT to metallic tungsten several complex steps accompanied with different operational atmospheres and temperatures. Furthermore, the high-temperature methods usually failed to produce ultrafine tungsten particles.

Thermal plasma technology has widely used in industrial applications. RF electric field using reactive gas without electrodes have the special advantages of large volume, clean high-energy, chemical reactivity, and the fact they are especially suitable for the synthesis of high purity materials. RF thermal plasma has been extensively used for the synthesis of ultrafine powders, thin film deposition, spheroidization, and so on. Thus, a production method in which hydrogen plasma reduces APT for preparing nanosized tungsten powders using RF induction plasma has been invented.

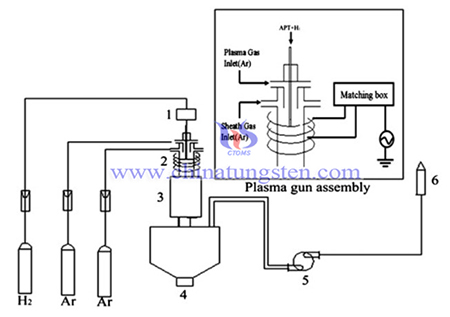

The synthesis of W nanopowders were achieved by RF thermal plasma system under following setups: RF generator (30 kW, 4 MHz), a plasma generator with a downward plasma torch, a cylindrical reactor, a quenching chamber, a precursor feeding system, a powder-collecting filter, a gas delivery system, and an off-gas exhaust system. The plasma torch consists of three main elements: a four-turn water-cooled induction coil, a confinement tube, and a water-cooled injection probe. The reactor consists of a vertical quartz tube of 6 cm inner diameter and 25 cm length. The quenching chamber connected to the bottom of the reactor is a water-cooled two-layer stainless-steel box which cools the outgoing gas.

APT (99.9%) was used as the precursor, Argon (Ar, 99.9%) was used as the plasma gas and hydrogen (H2, 99.9%) was used as the reducing agent. Before delivering the precursor into the plasma flame, the reactor was heated by the plasma flame for about 5 min until the system reached a steady level. The precursor APT powder was fed into the plasma flame under the carrier gas H2 and the tungsten powders produced were collected at the bottom of the chamber. For stable operation of the induction plasma torch, the parameters for plasma processing are very important.

The phase composition, morphology and particle size distribution of the tungsten nanosized powders were characterized by X-ray diffraction (XRD), field-emission scanning electron microscope (FESEM), and transmission electron microscopy (TEM). The results showed that the crystallized product is spherical tungsten nano-powder with a particle size of less than 50 nm.

In conclusion, tungsten nanosized powders have been successfully synthesized in one step by an RF induction thermal plasma using APT as the precursor. The phase of synthesized products could be controlled well by varying the feeding rate, and the particle size could be well tuned by adjusting the quenching rate. The synthesized powders, all with a uniform particle size of less than 50 nm, are approximately spherical.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com