New Catalyst Using Ammonium Paratungstate as Material for Pyrolysis of Elephant Grass

- Details

- Category: Tungsten Information

- Published on Sunday, 06 June 2021 19:34

Catalytic pyrolysis has gained a lot attention due to its function to improve the quality of bio-oil for transportation and other bio-refining processes. The application of catalysts promotes cracking reactions of heavy molecules and deoxygenation reactions of pyrolysis products, resulting in a lighter bio-oil of lower viscosity, higher calorific value and chemical stability; thus enabling its storage, transportation and use as an energy carrier for electricity and heat production or in chemical processing to obtain bio products.

Generally, when using a solid catalyst as a primary catalyst mixed with biomass (in situ) or as a secondary catalyst isolated in a catalyst bed (ex situ), what actually happens is the pyrolysis of biomass followed by the conversion reaction of pyrolysis vapors. However, the catalyst decreases the vapor yield and increases the gas that is produced by decarboxylation and decarbonylation reactions.

Elephant grass is a native grass widely spread in Africa with high productivity, short production cycle, low requirement of additional nutrients for growth, and good energetic properties. A new catalyst is synthesized using ammonium paratungstate as material for pyrolysis of elephant grass. The synthesis process of new catalyst is as below:

RHA-MCM-41 was synthesized by hydrothermal method using rice husk ash (RHA) as sources of silica, cetyltrimethylammonium bromide (CTMABr) as a template, sodium silicate, and distilled water. The reactive gel with a molar composition of 1.0 CTAMBr: 4.0 SiO2: 1.0 Na2O: 200 H2O was put into a Teflon vial in a stainless steel autoclave, and heated at 100 °C for 120 h. The pH correction was performed every 24 h, adjusted to a range between 9 and 10 with a 30% solution of acetic acid until it stabilized. After calcination at 550 °C, the RHA-MCM-41 was impregnated with ammonium paratungstate (99.99% - H40N10O41W12), for deposition of 15–30% of WO3 and calcined at 550 °C, resulting in W15/RHA-MCM-41 and W30/RHA-MCM-41. The W15/RHA and W30/RHA catalysts was prepared by wet impregnation of ammonium paratungstate in the RHA, calcined at 550 °C, 10 °C min−1, for 180 min, thereby obtaining 15 and 30% of WO3 over rice husk ash silica. The tungsten content (15 and 30%) as well as material support structures (silica and mesoporous silica) were evaluated on the catalytic conversion of EG pyrolysis vapors.

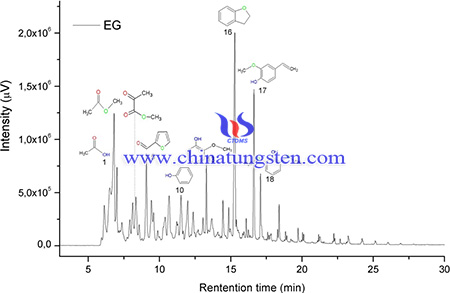

In summary, a new catalyst using ammonium paratungstate as material for pyrolysis of Elephant grass has been successfully produced. The deoxygenated reaction pathways were difficult to identify, but the main influence on the deoxygenation reactions of pyrolysis products was the WO3 active sites promoted by the redox ability of the catalyst, since aromatic compound yield increases with the increased WO3 content on the catalyst. Increasing the catalytic bed temperature has a significant influence on aromatic compound yield, mainly on the yield of benzene, toluene and styrene which are usable products. The WO3 supported on rice husk ash (RHA) has been shown to be a low-cost catalyst for converting lignocellulosic biomass pyrolysis products into aromatics.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com