Synthesis of WO3 Nanoscale Films Using APT for PEC Device Applications

- Details

- Category: Tungsten Information

- Published on Sunday, 06 June 2021 19:27

Since the report of electrochemical photolysis of water using TiO2 under UV illumination, it has been widely concerned on the clean energy that is generated on semiconductors driven by solar energy [1]. Simultaneously, binary metal oxide photoanodes such as ZnO, TiO2, WO3, and α-Fe2O3 had been had been widely investigated on hydrogen generation, photovoltaic device and photocatalysis. Among these materials, WO3 has been developed as a promising n-type semiconductor, since WO3 (2.7 eV) can absorb more photons than ZnO (3.2 eV) and TiO2 (3.0–3.2 eV) and possess an appropriate hole diffusion length and inherently good electronic properties. However, the sluggish kinetics of oxygen evolution reaction and rapid recombination of photon-generated carriers are the main obstacle for WO3 in terms of practical applications . Heterojunction structure, such as WO3/BiVO4 is considered as the feasible route to facilitate the charge carrier transfer of WO3.

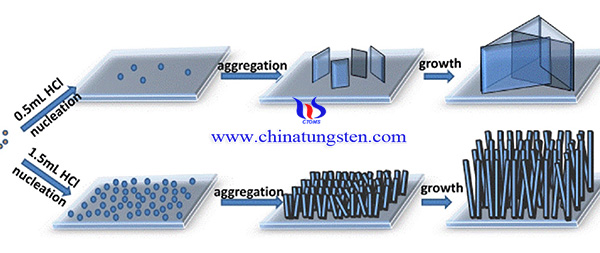

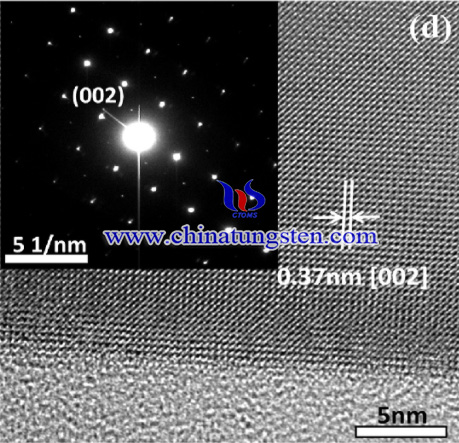

Thus, A synthesis of WO3 nanoscale films using APT as raw material for PEC device applications has been successfully performed. The amount of HCl had a fatal influence on the morphology could be easily controlled by adjusting the applied amount of HCl in the synthesis procedure. The synthesis process of the modified WO3 nanoscale films is as following steps:

1 g of ammonium paratungstate (APT) was dissolved in 100 ml ultrapure water (18.25 MΩ cm), and then 0–5 ml of concentrated hydrochloric acid (37 wt%) was added and stirred to get the translucent yellow precursor solution. After that, 2 ml of hydrogen peroxide (H2O2, 30%) was added and stirred for a few minutes to form a stable and transparent precursor solution. The fluorine doped tin oxide (FTO) glasses (1.5 × 2 cm, 2.2 mm, 7 Ω/cm2) were previously ultrasonically cleaned and treated in the ultraviolet ozone cleaner before use. Then, 18 ml precursor solution filled in the 23 ml sealed Teflon reactor and kept at 160 °C for 4 h. The as-prepared WO3 samples were then annealed at different temperatures for 2 h.

In summary, A synthesis of WO3 nanoscale films using APT as raw material for PEC device applications has been successfully performed. The morphology could be easily controlled through adjusting the acidity of solution. The addition amount of HCl plays an important role to control the WO3 morphology. Approximately 55% improvement in photoelectrochemical catalytic efficiency was obtained by the WO3 nanoplates photoanode in comparison to the nanorods photoanode in a methyl orange degradation experiment.The improvement of PEC behavior in the nanoplate arrays could be attributed to the preferable charge separation and enhanced interfacial transfer presented by the EIS and OCVD results. Furthermore, the WO3 photoanode with the nanoplate arrays exhibited better MO degradation activities than that with the nanorod arrays. Therefore, a facile method to synthesis effective photoanodes has been presented for PEC devices by modifying their morphology to enhance their efficiency.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com